The amount of energy lost by rolling tires directly impacts electric vehicle (EV) range and internal combustion engine (ICE) fuel efficiency. Manufacturers worldwide use MTS Rolling Resistance Systems to gain the data needed to optimize tire efficiency and test in accordance with ISO and SAE standards.

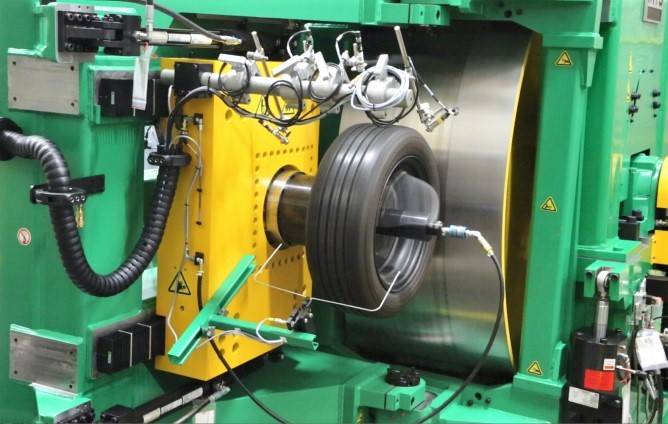

Alex Novak - Tire Systems Product Manager explores the capabilities of the versatile MTS Tire Rolling Resistance Measurement System. This high precision measurement system features an AC electric motor powered road wheel mounted in an ultra-stiff frame with tire test carriages on either side. The right carriage applies radial loading to larger truck and bus tires, while the left carriage applies radial, slip angle, and camber angle loading to passenger car and light truck tires. Industry-proven MTS controls and tire test application software enable a full array of template-driven ISO and SAE standards testing, as well as more advanced, custom time history playout.

Laser-aligned and calibrated on a system level, the MTS Tire Rolling Resistance System captures highly precise tire rolling resistance data by measuring forces at the tire spindle, or measuring torque on the road wheel.

Laser-aligned and calibrated on a system level, the MTS Tire Rolling Resistance System captures highly precise tire rolling resistance data by measuring forces at the tire spindle, or measuring torque on the road wheel.

Truck & Bus Tire Carriage: applies up to 60 kN radial force for performing conventional tire rolling resistance tests, such as Steady State (ISO 28580, SAE J1269) and Coast Down (SAE J2452).

Passenger Car & Light Truck Tire Carriage: applies up to 15 kN radial force for conventional testing; additional slip angle (± 2 deg) and camber angle (+6/-2 deg) motion inputs enable simulation of vehicle suspension setups and real-world driving cycles, such as WLTP.