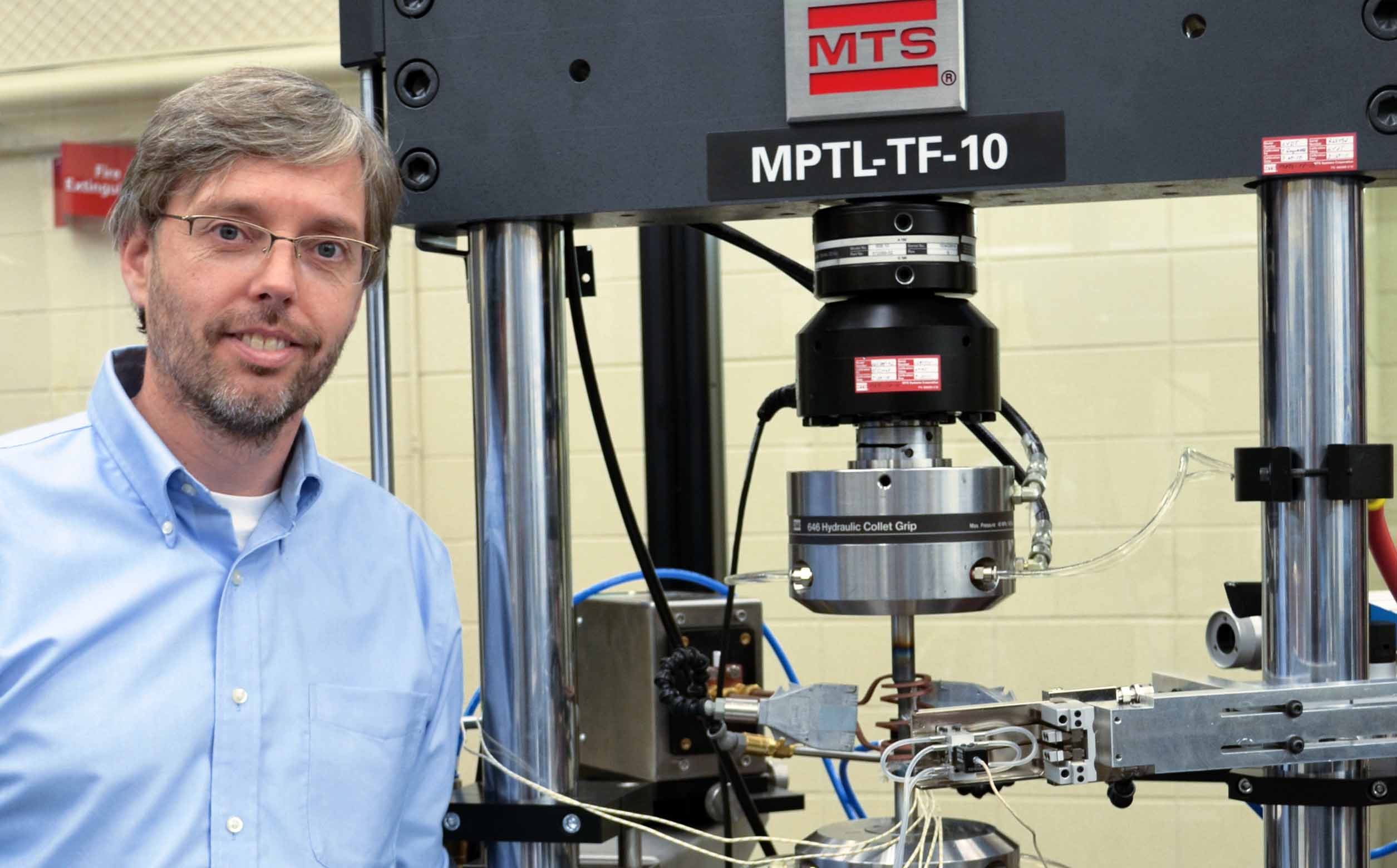

Dr. Christoph Leser has nearly 30 years of experience as a researcher, test engineer, application engineer and test consultant, and is a subcommittee chairperson for ASTM. Here, Dr. Leser describes how materials researchers can achieve consistent results in thermomechanical fatigue (TMF) testing.

Q: Why is there growing interest in TMF testing?

A: Two of the most exciting areas in materials R&D today are related to the turbines used in aerospace and power generation. In both cases, designers are pushing operational efficiency and reliability beyond all previous expectations. To do that, they need turbine components and structures that can withstand higher temperatures for longer periods of time under a variety of cyclic loading conditions. Materials under investigation include innovative superalloys, ceramic matrix composites, ceramic coatings and others. Knowing how these materials react to simultaneous changes in temperature and load make TMF an essential part of the R&D process.

Q: Can you describe the mechanics and objectives of TMF testing?

A: TMF testing is a kind of fatigue testing that simulates the real-world service conditions of engineered components as closely as possible. Specifically, TMF tests characterize the response of materials to simultaneous cyclic mechanical loading and fluctuating temperature, which produce a synergistic response that is not easy to predict using isothermal fatigue testing. The data generated through TMF testing helps researchers model component behavior as well as validate existing models in a controlled test environment.

Q: What are the unique challenges of TMF testing?

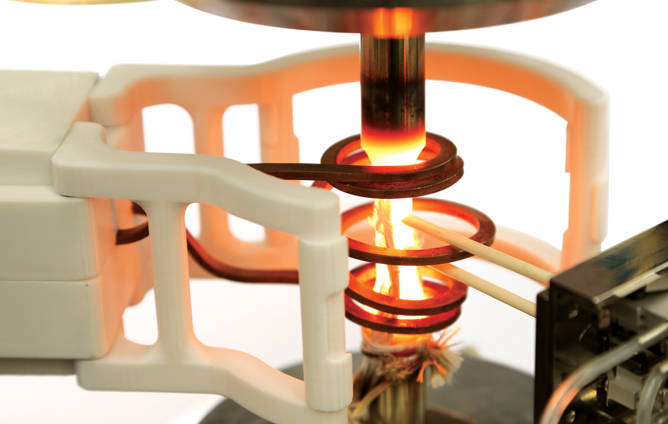

A: TMF can be difficult because it uses in-phase and out-of-phase mechanical and thermal cycling. The phase shift between temperature-induced and mechanically induced strain invites numerous interpretations of material behavior. You need to apply heat using radiant or induction methods, which may require cooling. Test equipment and fixturing must be able to withstand high temperatures. Capturing accurate data is hard because high-precision systems behave differently at very high temperatures. The type of material being tested influences each setup, and there are many options for instrumentation, heating, cooling and fixturing. For all of these reasons, TMF testing tends to be customized and complex.

Q: Given this complexity, how can researchers hope to achieve consistency from test to test and lab to lab?

A: Testing standards, such as ISO 12111 and ASTM E2368, outline the best practices for characterizing materials subjected to simultaneous thermal and mechanical loads. Additionally, the European Validated Code of Practice for Strain-Controlled Thermomechanical Fatigue Testing, which was created by a consortium of international partners, is another good resource for establishing testing consistency. As I mentioned, one of the big challenges with TMF is that total strain includes thermal and mechanical components, and you have to know the precise distribution. For this reason, the Code of Practice reduces the phase shift command to two possibilities: in-phase (maximum strain at maximum temperature) and out-of-phase (maximum strain at minimum temperature) cycling. The code also includes all the steps required to perform the test, from calibration to data reporting.

Q: How can researchers be confident they are meeting the requirements in the Code of Practice?

A: Researchers can adhere to the code — and address the complexity of TMF testing — using advanced software solutions. MTS offers a TMF template for MTS TestSuite™ Multipurpose software for testing to ASTM and ISO standards as well as the European Validated Code of Practice for Strain-Controlled Thermomechanical Fatigue Testing. The template is completely transparent, providing full insight into its algorithms and calculations, so researchers can use it to interpret standards in different ways, and can modify the template to gain new insight. All of this flexibility allows them to perform many different TMF tests for a diverse array of materials and specimen geometries.

Q: What features of the template and the software are particularly suited to TMF testing?

A: Each task from the Code of Practice is represented in the template by a button from the command panel, and each button is defined by a program block that the user can modify. Basically, if you can see it, you can change it. This applies to test calculations and workflow, as well as the visual representation of data during the test, which offers unlimited views and is user-configurable. It also applies to results, so you can export the data and present results in the format that works best for your needs.

Q: What is coming up next for TMF testing?

A: One of the biggest trends in testing is the integration of modeling. MTS, along with one of our partners, has developed a solution to better predict heating capabilities. This new solution allows us to model the specimen, coil and grips to understand what values, rates and distribution of temperature can be achieved for the specimen prior to building any hardware.