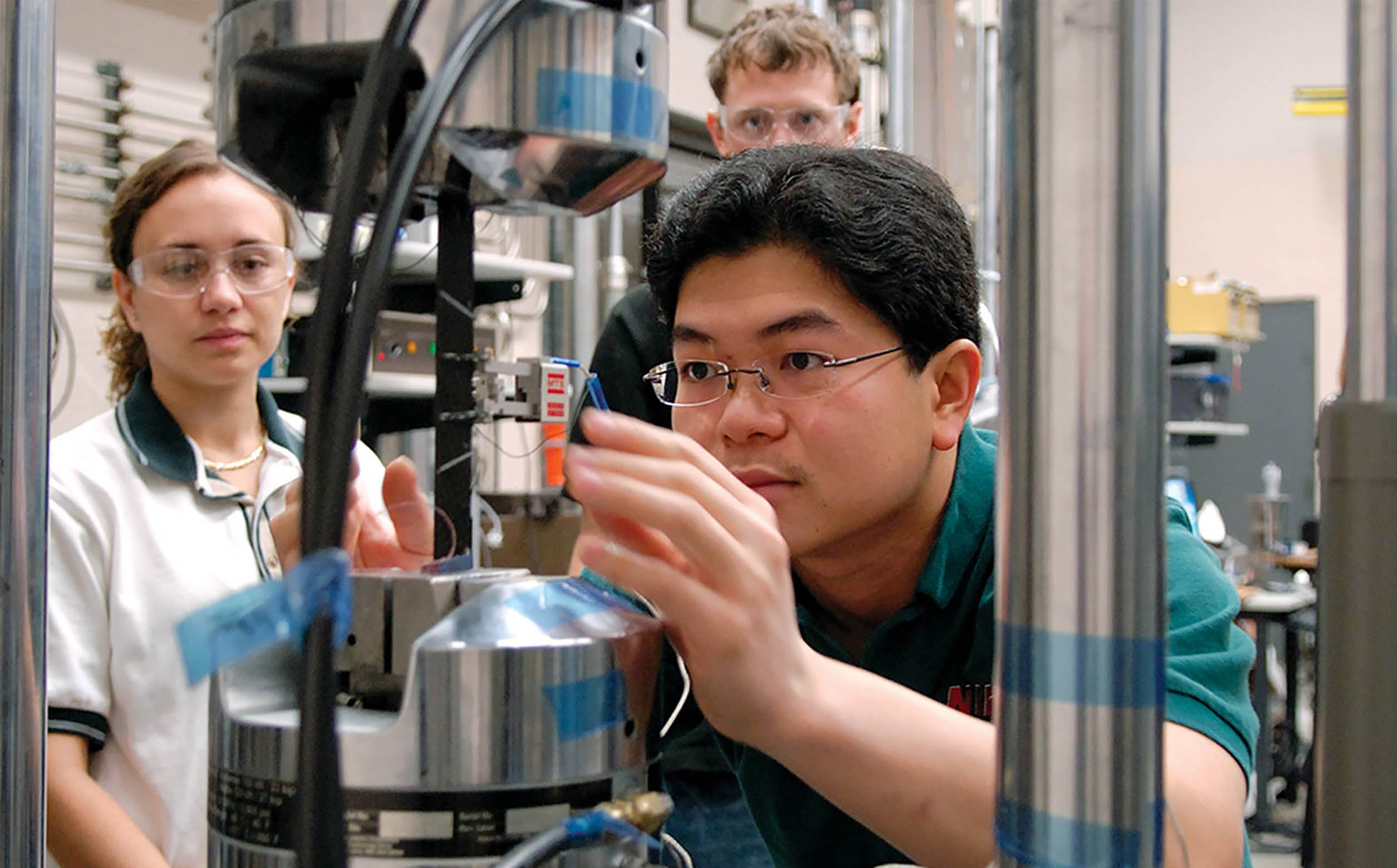

Hands-on sessions with test equipment are the ideal way to expose learners to central principles of materials behavior. But maximizing each student’s time with these systems can be difficult, especially when lab resources are limited. Within a very small window of opportunity, students in a typical lab session need to work through test setup before they can observe the different modes of material deformation and rupture response. Running a good test simply takes time.

To help instructors improve learning outcomes, MTS provides two critical resources:

- Basic materials testing curriculum that includes lesson plans and homework

- Simulation software so that students can run virtual tests and strengthen their understanding of materials testing concepts.

Together, these resources enable students to witness a virtual test in the classroom, perform virtual tests in a computer lab and perform actual tests in the laboratory with greater ease and efficiency.

Developed by Dr. Christoph Leser, the curriculum was inspired by the approach test labs take to problem solving during product development. Specifically, the engineering workplace often introduces a layer of simulation between theoretical design and prototype construction. This is done for reasons familiar to university instructors: lab resources are limited but pressure to perform more tests in less time – without sacrificing accuracy – is intense.

“Using software to simulate mechanical testing can transform how materials science students learn,” Dr. Leser said. “When the identical graphical user interface is used to conduct virtual and physical materials tests, it enhances every student’s understanding of the material’s plastic yielding, stress-strain relationships, fatigue, crack growth and fracture, whether they are watching in the classroom, studying on their own or working with an actual test system.”

Establishing consistency from the lecture hall to the laboratory helps course instructors offer a more fully integrated virtual and physical curriculum. This equips students to handle all the tasks associated with test set-up, execution and data analysis more quickly, which makes the laboratory experience more efficient. An integrated curriculum also helps students understand and appreciate both the value and limitations of modeling approaches in describing material behavior.

CONNECTING THE PHYSICAL & THE VIRTUAL

For a discussion on yield strength, for example, students are presented with the design of a clutch linkage. The coupler link is a two-force member experiencing a 4.5 kN tensile force. If the force is too high, the part will yield. Students are asked to design the link by choosing an appropriate width “w” for a link made with a thickness “t” of 6 mm steel plate. To complete the design, students need to know the yield strength of the steel plate. The lab section teaches the student how to measure yield strength through measurement of the stress-strain curve and calculation of offset yield strength.

MTS TestSuite™ Software allows students to define and execute tests and analyze test data either in the lab or the classroom. Offline licenses that replicate the lab’s system software provide students a simulation environment with software that can be loaded on a laptop or other computers not connected to the test system. Professors can then use both the physical and virtual environments to optimize instructional efficiency.

MTS TestSuite test templates can be run virtually or with an in-house materials test system. In both cases, the user experience is identical. MTS TestSuite software facilitates the transition with the use of the Python™ programming language, which has very little abstraction and makes it easier for students to move from the equation to the test program. Code is written the same way as a manual calculation would be performed. In addition, because Python is an open source language, many different sample programs and documentation are freely available.

ADVANTAGES OF INTEGRATION

There are several important advantages to integrating lectures, simulation and physical testing. Students gain direct experience with the material property needed to successfully complete the design exercise. Integration also provides a direct illustration of material behavior, prompting discussion of more advanced concepts, such as why materials yield, what defines ductility and why some materials are stronger than others.

In addition, students become familiar with the details of test methods, concepts, procedures and vocabulary as well as how to collect and interpret data, extract property values and identify where empirical results are used in analysis. In other words, an integrated curriculum effectively prepares students to perform real material tests. And they can do so at their own pace.

“All the aspects of running a good physical test, from specimen selection to alignment to mounting to running the test and analyzing data, take time and experience to master,” Dr. Leser said. “None of these is easy for the novice. But with an integrated curriculum, students can practice all these steps in a faster, easier way in a simulated environment.”