The global growth of train travel is increasing demand for new passenger rail cars, which is welcome news for manufacturers around the world. At the same time, these new cars must meet higher expectations. Modern passenger rail cars need to travel at higher speeds, provide a comfortable ride, maximize energy efficiency, and of course achieve full regulatory compliance.

Addressing these needs simultaneously presents a tough set of design challenges. Efficiency depends on removing weight, but this can’t affect stability. Stability becomes more difficult at high speeds, and the fastest rail cars in the world now run up to 350 kilometers per hour. Ride comfort is also more difficult to achieve at high speeds.

Because these factors are related, manufacturers must be able to optimize new designs in order to manage the trade-offs effectively. For example, a stiffer bogie might provide greater stability but less rider comfort. Roll bar stiffness can be changed to deliver better handling or a more comfortable passenger experience, but not both at the same time.

Product development teams are under intense time pressure due to high market demand, and designers must work quickly. This is where mechanical testing becomes very useful.

CHALLENGES IN THE LAB

In the test lab, component designers can examine many iterations of a new design relatively quickly in a highly controlled and repeatable manner. Test results reveal coefficients and other factors that can be fed back into virtual models of components and subsystems to make them more accurate. This helps speed up the process of analyzing and improving new designs.

The lab offers its own challenges. The list of relevant tests is long, and each one typically requires a different type of test system with a unique setup. Acquiring the systems necessary to optimize new bogie designs can be expensive. Configuring and running the tests can become inefficient when multiple systems are in use.

The biggest challenge of all is the need to test the entire mechanism, not just a single component. This may seem counter intuitive, but advanced design engineers understand that testing individual parts does not provide the same accuracy or insight as testing a complete bogie.

Although discrete component tests are easier to manage and can be performed quickly, they do not provide the same accuracy as testing all the components as a system. Component interactions produce unexpected behaviors due to friction and off-axis motion. These interactions can’t be replicated by evaluating each component separately. Engineers have long suspected this was the case, but only in the past decade has it become obvious. Virtual models have become more sophisticated, yet engineers have been unable to predict system performance on the rail accurately based on individual component characteristics.

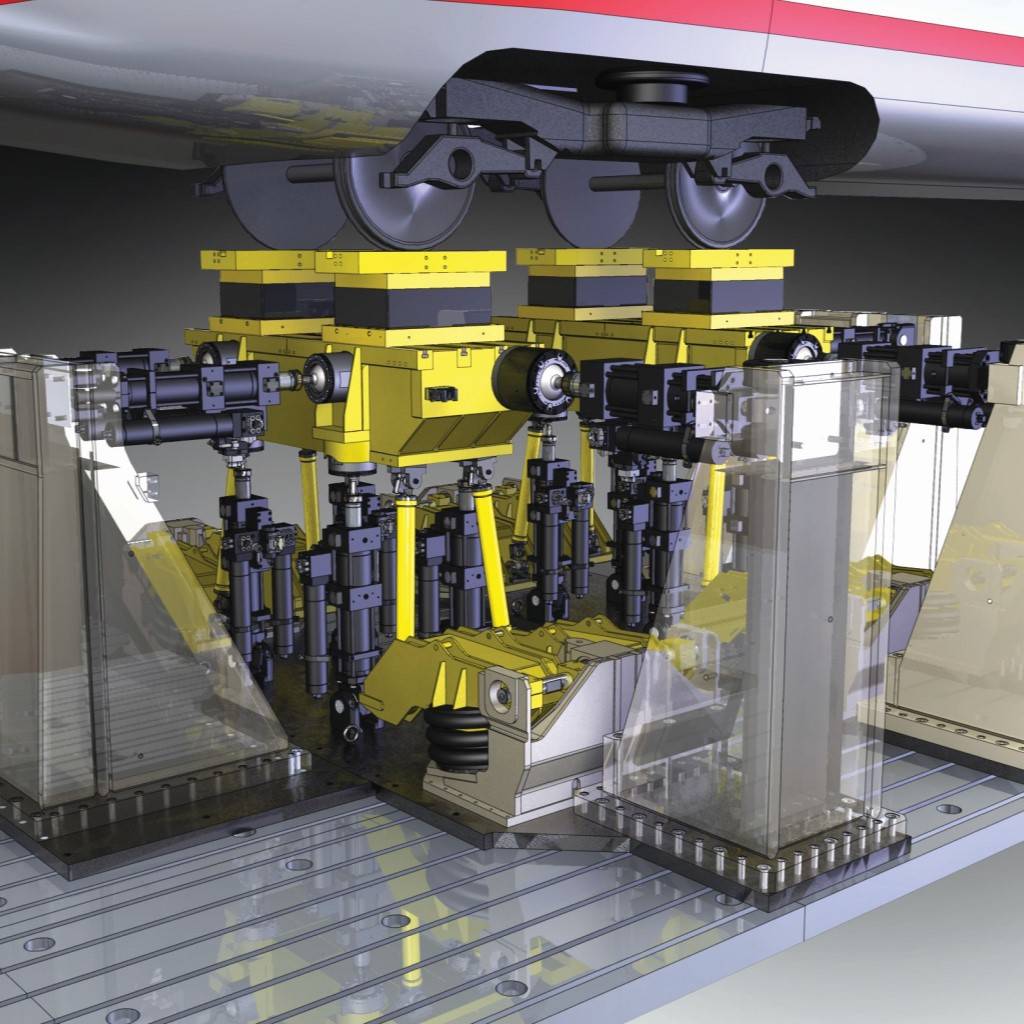

Recently, an innovative rail car test system has been put into service that can be used to measure the kinematics and compliance of a complete bogie mechanism. The system, supplied by MTS Systems Corp., can also be used to provide characterization, basic durability and vibration testing, all in a single system.

PRIMARY AND SECONDARY SUSPENSION TESTING

Currently installed at a high-speed passenger rail car manufacturer in Asia, the new bogie measurement system provides the size and force required to load a complete bogie as well as a complete rail car. The test system incorporates considerable instrumentation designed for extremely precise measurements of these complex mechanisms.

The complexity comes from the many ways test data can be distorted. To ensure accurate results, test systems must be able to prevent (or compensate for) all of the following phenomena: phase shift caused by lash or damping; signal distortion and noise caused by system and specimen resonances; and force measurement errors arising from cross-talk, temperature compensation of the transducers, thermal expansion and contraction of fixtures and specimens, calibration errors, slippage, drift or damage to transducers, mounts, cables or conditioners. In many cases, several signals are combined to calculate the desired result, compounding the total error.

Some of the most important tests the system performs are those of the primary suspension, which includes all of the components between the bogie and the axle (spring, coil spring, torsion bar, rubber biscuit, etc.). While the primary suspension affects steering, handling and to some degree rider comfort, engineers need to understand the complete wheelset mounting and suspension system in great detail to optimize new designs. The stiffness of the primary suspension is in the same range as bogie frame stiffness, and the interaction between the two determines overall bogie handling response. For this reason, the new test system is uniquely designed to measure the individual component contributions or complete assembly characteristic as an integrated system.

The primary suspension stiffness test involves fixing the secondary suspension, mounting linear variable differential transformers (LVDTs) at the axle bearing housing and bogie response points, and applying programmed force or displacement in each of the desired degrees of freedom (DOF). To achieve a useful result, engineers need to ensure the accuracy and resolution of load cells and LVDTs, maintain a constant temperature in the lab, and take measurements at different rates to evaluate damping characteristics. It is important to measure bogie stiffness in each direction, not just vertical, because stability is a function of combined multiaxial displacements, not only vertical. During cornering, for example, the bogie warps (deforms in yaw axis) and the warp stiffness is critical to stable steering.

This same setup can be used to perform a primary suspension damping test and evaluate damping in relation to spring stiffness. Test data from primary suspension testing is very helpful for feeding back into virtual models of the bogie for both model generation and validation.

Another important set of tests are those done on the secondary suspension, which is located between the top of the bogie and the bottom of the rail car. For these tests the primary suspension is fixed and the secondary suspension – typically a pair of air bags – is mounted to multiaxial load cells. A simulated rail car fixture is constrained in 3DOF and controlled in the remaining 3DOF to present the secondary suspension with the same loads and deformations it sees in service. This allows the stiffness and damping characteristics to be evaluated. Due to the canted shape of the air bag “hat,” predicting lateral and roll stiffness is particularly challenging. The elastomeric material deforms in unpredictable ways, and these movements greatly affect ride comfort.

ADDITIONAL PERFORMANCE TESTS

Another type of test this system can perform is steering resistance torque measurement, in which the bogie is rotated under the simulated rail car and its stiffness is measured. To run this test, equal and opposite lateral loads or displacements are applied to each axle. Tension/compression and longitudinal forces are set to zero and vertical actuators are commanded to maintain the desired force or fixed planar motion at the wheels.

In addition, the test system can be configured to test the suspension coefficiency for straight or curved track. In this test, the specimen is a full (or simulated) rail car with angle-measuring gyros on the tables, bogies and car body. The test involves raising the wheels on one side of the bogie to a desired super-elevation and measuring bogie and car angle relative to table angle. These relationships can be difficult to predict due to the many elements in the complete suspension. Manufacturers can use a similar test to understand the overturning coefficient, which is vital for ensuring ride comfort and safety.

Complete rail cars can be evaluated as well. If engineers want to understand dynamic response for coefficient tests, the system can be commanded with broad band-shaped noise or specific wave shapes, such as a sine wave. The rail car body response is measured and its natural frequency can be estimated from the resulting data using test software.

Other tests the system can perform include center of gravity location, moment of inertia testing and real-time playback of on-rail operating data.

While it is true that a multipurpose performance testing system represents a significant capital investment for the lab, it provides an equally significant return on investment through its ability to accelerate the test schedule, reduce costs and improve the accuracy of test data and specimen characterization. Ultimately these capabilities will enable rail car and bogie manufacturers to improve the accuracy of models, achieve innovation faster, make higher-quality vehicles and build lasting competitive advantage.