CUSTOMER CHALLENGE

Bell Helicopter runs a bustling mechanical test facility in Fort Worth, Texas. The 25 engineers and technicians there manage all types of testing on both new and legacy Bell models, with responsibilities ranging from fatigue, static and vibration testing to hydraulic and fuel system component characterization.

According to Don Ross, a test engineer with a 35-year history at Bell Helicopter, it was recognized a few years back that the facility’s once state-of-the-art controls were becoming an increasing hindrance to productivity. “We had a lot of old servocontrol technology here, and it definitely had not improved with age,” Ross said. “We clearly needed to upgrade our control platforms, but we hesitated due to the complexity associated with getting new controls to function within our existing proprietary data acquisition and command system.”

Adopting a new control platform at the Bell test lab would be an undertaking indeed. Significant interface customization would be required to connect the new controllers to the various test rigs in use across the facility. To further complicate matters, custom code development would be required to interface with the existing Bell data acquisition and command system.

The new controllers would also have to be flexible enough to move from station to station, as well as expandable to support the ever-increasing channel counts accompanying today’s higher data processing speeds. “Almost all of our test stands are one-of-a-kind buildups designed to test a specific component or structural element of an aircraft,” Ross said. “And since we move our boxes around a lot and use them with different test rigs, it would be mandatory for us to be able to roll up the new controllers to an existing test station, plug in the cables, do the necessary setup, and start running our tests.”

Ross knew a challenge of this magnitude required a testing solutions partner with expertise in both system integration and custom development. “As we began talking to MTS, the prospect of upgrading our control platforms became increasingly realistic,” Ross said. “We concluded that MTS could do the custom work necessary to get us where we needed to be, with minimal disruptions to our busy schedule. So we committed to upgrading our lab control systems with MTS.”

MTS SOLUTION

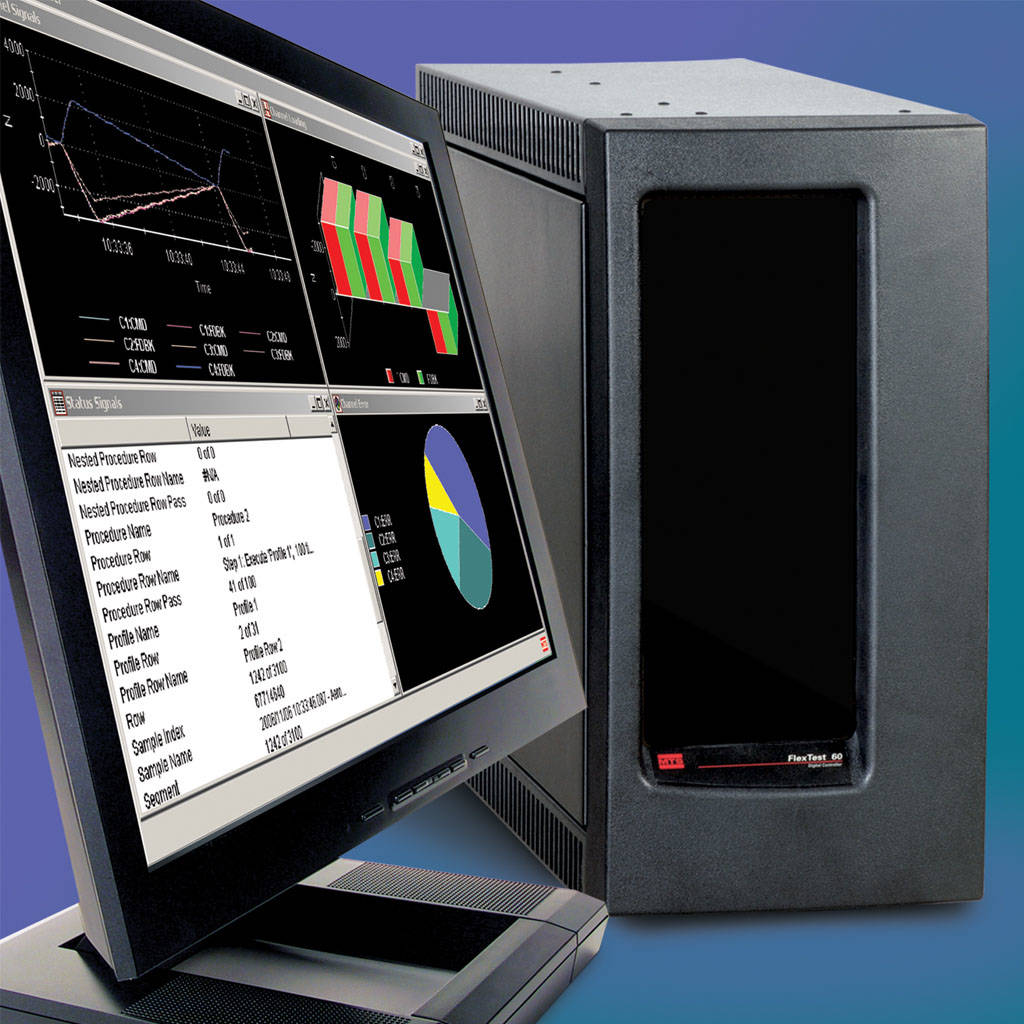

To provide test labs with a digital control platform that could meet current and future testing needs, MTS recently unveiled the FlexTest® Controller Family. All FlexTest controllers share a common set of hardware boards and user interface tools, helping to drive hardware standardization and increase testing productivity. These modular controllers are also easily configured to accommodate a full spectrum of test applications.

In the summer of 2008, Bell Helicopter selected for their new control platform the FlexTest 60 controller driven by best-in-class AeroPro™ Control & Data Acquisition Software. Flexible, 4-channel FlexTest 60 controllers can be easily arrayed into “Master-Slave(s)” configurations to accommodate higher channel-count tests. This involves a custom multi-box approach that connects the controllers in a “daisy chain” with the in-house data acquisition and command system at the center.

Bell Helicopter has since purchased ten more FlexTest 60 control systems.

“Completely upgrading our lab control systems was a huge project, but we were amazed at how smoothly and efficiently the entire process unfolded,” Ross said. “And equally important, MTS completed all of this custom work offline, minimizing disruptions to our busy schedule. And once the work was done, the new controllers were basically ready for use.”

CUSTOMER BENEFITS

With the upgrade to the FlexTest control platform now complete, Ross anticipates gains in testing efficiency and productivity. “Our servocontrol systems are now more reliable, and our test setups are much faster and easier,” he said. “It’s a welcome upgrade for everyone at our facility.”

The ability to move FlexTest controllers around the facility and connect several together as needed provides the flexibility required for a lab as busy as Bell’s mechanical test facility, whether test engineers are running certification protocols or analyzing data to improve testing techniques.

“We can now easily accommodate tests with higher channel counts and close the loop on as many channels as needed,” Ross said. “It’s reassuring to see such a clear migration path forward with our controls, and to be backed by the knowledge and support that we’ve grown to expect from MTS. We look forward to expanding our test capabilities on the FlexTest platform for many years to come.”