Under relentless pressure to shorten development cycles and reduce costs, auto manufacturers are increasingly exploring ways to use analysis tools to perform meaningful virtual evaluations of vehicle designs early on, well before the availability of physical prototypes. The ability to obtain accurate predicted - or calculated - loads in this fashion augments the effectiveness of component physical testing, enables early identification and elimination of design flaws, reduces the need for rework and reliance on prototypes, and streamlines design validation.

A variety of simulation approaches have been devised for obtaining accurate calculated loads earlier in the vehicle development process. One method, the Virtual Proving Ground, involves “driving” a vehicle model over a digitized road. While having the advantage of relying entirely on virtual models, this approach yields inaccurate loads that are difficult to validate through physical testing. A Semi-analytical method, on the other hand, uses spindle loads acquired from an existing vehicle to excite the vehicle model. This delivers better results than the virtual proving ground, but establishes boundary conditions not entirely appropriate for the vehicle model, so calculated loads are still incorrect and difficult to validate. A third method, Virtual Testing, overcomes these problems by integrating a model of an actual physical test system into the simulation to excite the vehicle model.

Virtual Testing is the simulation of a physical test, using finite element analysis tools, multi-body dynamic analysis tools and RPC iteration techniques to derive accurate loads, motion and damage information of a vehicle system very early in the development process. The advantages of this approach are numerous. First, because it is easier to model the constraints of a physical test system than proving ground surfaces or tires, virtual testing establishes far more effective boundary conditions than the other methods. Second, virtual testing leverages an arsenal of proven, well-established physical testing tools and techniques, which have demonstrated utility in the analysis realm. And third, the incorporation of a modeled physical test system greatly streamlines the validation of results through subsequent physical testing and provides opportunity to improve physical test setups and fixtures designs. Spanning the analytical and physical test disciplines, virtual testing requires advanced knowledge of both CAE tools and physical testing, the development of a process to link RPC Pro software and analysis models, and preferably some degree of virtual testing exposure and experience.

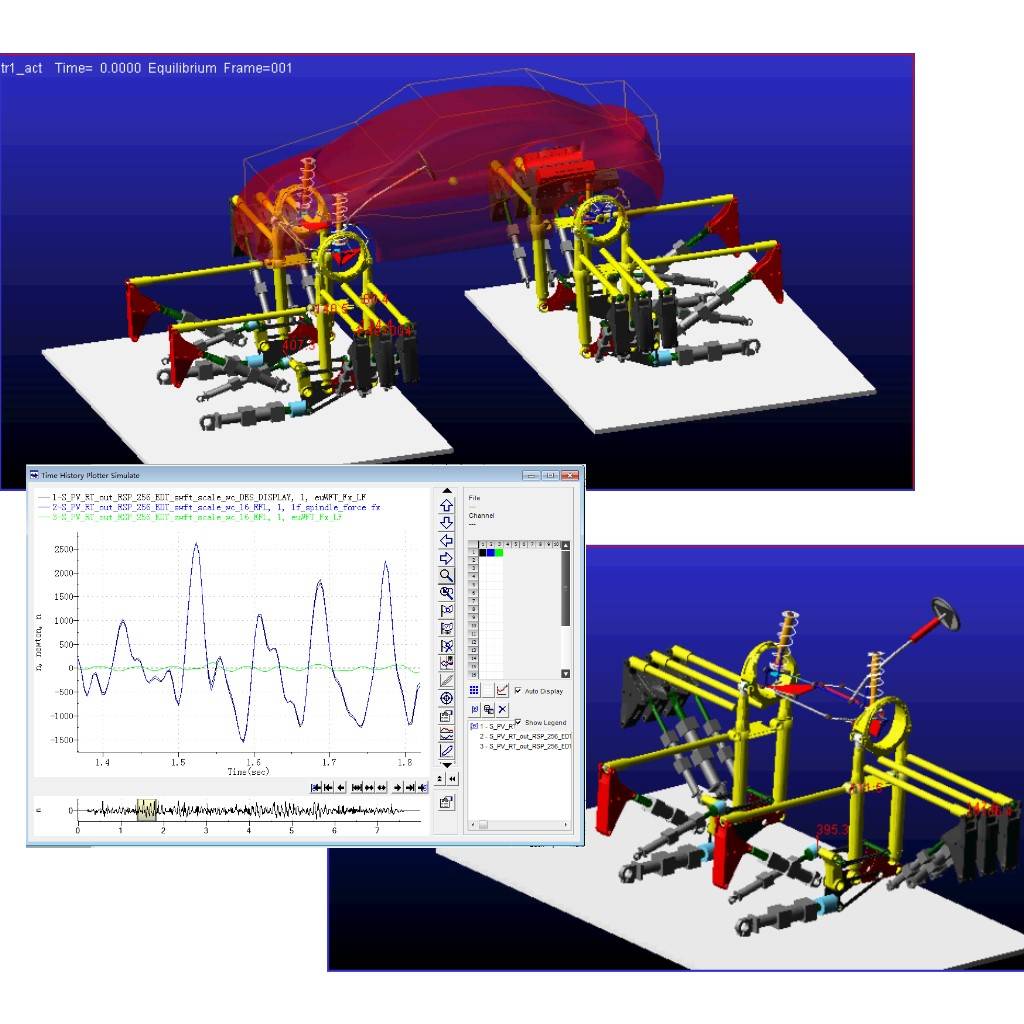

For years, MTS has focused on refining the virtual testing approach, conducting a variety of demonstration projects with key customers like Hyundai Motor Company (HMC) and Thermo King to evaluate various methodologies. These projects included virtual tests of full vehicles and subsystems, all yielding satisfactory correlation with either measured road load data (RLD) or actual physical testing. The basic methodology gleaned from these experiences comprises the following steps: 1) Connect test rig models with specimen models; 2) Couple the models with RPC Pro; 3) Reproduce road load data on the virtual test rig; 4) Extract calculated loads; 5) Create the physical component/subsystem test.

A recent demonstration project with the State Automotive Institute of China (SAIC) provides an excellent example of this methodology in practice:

- Connect test rig models with specimen models

At the outset of the project, MTS built a collection of test rig models in ADAMS, Simulink, and ADAMS-Simulink co-simulation formats. The MTS test rigs that were modeled included a variety of Model 329 Spindle-coupled Road Simulators, a Model 353.20 Multi-axial Simulation Table (MAST) System, and a TestLine component test system. Select test rig components were also modeled, including a FlexTest digital controller, MTS actuators and servovalves, and an actuator transform that converts actuator displacement, acceleration and force into DOF displacement, acceleration and force. Due to project time constraints and the relatively slow simulation speeds of the more complex co-simulation models, the ADAMS/Car 329 model was coupled with SAIC full vehicle, front suspension and rear suspension models and ultimately used for the bulk of the virtual testing.

- Couple the models with RPC Pro

A virtual test server was developed to connect RPC Pro software and the ADAMS/Car 329 model. During testing, RPC Pro employs this virtual server to send drive files to the ADAMS model, initiate the ADAMS simulation and copy the response file from the ADAMS folder to the RPC Pro working directory. Additionally, a Matlab Interface Tool already existing in RPC Pro was used to couple RPC Pro with the co-simulation models.

- Reproduce road load data on the virtual test rig

The RPC iteration technique was then used to reproduce road load (spindle force) data collected from the proving ground for a variety of select events and maneuvers. Interestingly, initial RPC iterations on the virtual 329 rigs exhibited no convergence, suggesting flaws in the SAIC vehicle model. Subsequent analysis of the model did indeed reveal deficiencies, which were corrected in short order. With the model improved the RPC iterations finally converged, showing excellent correlation between desired and achieved signals and low RMS errors across all channels for both full and partial vehicle virtual simulations.

- Extract calculated loads

Upon RPC iteration convergence, calculated loads for any mechanical component or subsystem could then be readily obtained from the vehicle model as functions of time.

- Physical Test Creation

Load time histories extracted from the vehicle model were then used to define subsequent physical component tests. Once it is determined whether a part is subject to single axis or multi axis loading, the RPC Pro arsenal of test methods and tools can be used to define significantly accelerated component tests. For components under single axis loading, the Block Cycle method or Power Spectrum Density (PSD) methods can be used. For components subject to multi-axis loading, the Peak Valley Slicing method can be used. For situations where a component’s loading frequency needs to be preserved, the Time History Reproduction method is most appropriate; for these types of tests, RPC Pro features Fatigue Sensitive Editing which has the potential accelerate durability tests by a factor of 2 to 10. Once the loading signals are determined for each component, the same physical test system that the virtual test rigs were based on can be used to conduct the component test. Furthermore, a variety of compensation techniques in RPC Pro, such as Peak-Valley Compensation, Adaptive Inverse Compensation, and RPC iteration, can be used to make sure that desired loading conditions are accurately achieved during physical testing.

MTS’ ongoing exploration of virtual testing demonstrates that it is an effective means for accurately predicting component loads prior to the development of physical parts or prototypes. Once these calculated loads are obtained, the same RPC Pro tools and techniques used to obtain them can then be used to create and conduct the physical testing required to validate their accuracy, and the accuracy of the vehicle model. The potential impacts of effective virtual testing on the vehicle development are considerable. The availability of accurate predicted loads and subsequent earlier physical testing will minimize component and subsystem rework, reduce the need for multiple prototypes, and accelerate design validation. Also, the role of physical testing will evolve: while testing will continue to be necessary to achieve final validation of a vehicle design, it will increasingly be tailored to validate the accuracy of vehicle model. And finally, virtual testing will prompt the integration of analysis and physical test disciplines and cultures, prompting the advent of new efficiencies through the sharing of tools, processes and experiences.