CUSTOMER CHALLENGE

Nexxt Spine is a privately held medical device company dedicated to increasing procedural efficiency and patient outcomes for patients with debilitating spinal conditions. Addressing these concerns is critical as the world's population ages and spinal surgery becomes more commonplace.

Along with the deterioration that comes with natural aging, spinal tumors or trauma can cause decayed, diseased or collapsed discs that are immensely painful and need to be repaired. To address these concerns, Nexxt Spine, as a medical device company focused on designing, manufacturing, and distributing innovative spinal solutions, is employing MTS material test systems to develop bone healing spinal implants.

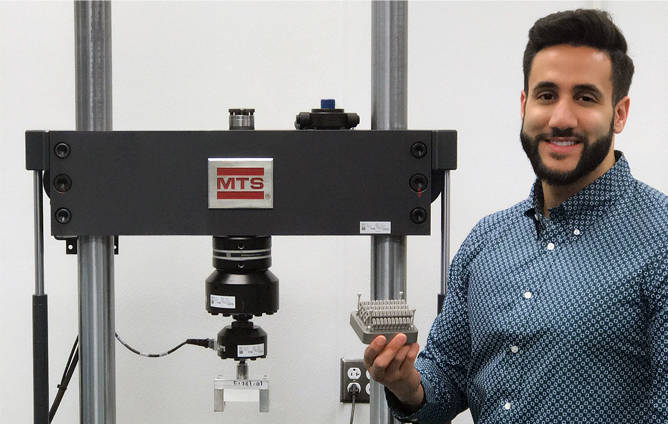

MTS SOLUTION

Nexxt Spine used an MTS Landmark test system to evaluate their 3D-printed, porous titanium spinal implants. "We've immersed ourselves in the additive manufacturing space completely and positioned our future business focus as pioneers in the design and development of spinal fusion implants that incorporate interlaced micro-lattice architectures with the goal of promoting osteoconduction, osteointegration and bony fusion," says Alaedeen Abu-Mulaweh, Nexxt Spine Director of Engineering. "Given the highly nuanced nature of these intricate micro geometries, the MTS testing platform has been our go-to solution for quantifying and tailoring the associated biomechanical performance attributes from day one."

CUSTOMER BENEFITS

MTS' expertise in creating systems for testing biomedical devices and simulating in-vivo conditions, combined with leadership in developing testing techniques for additively manufactured products, brings a unique set of knowledge to this type of testing application.

We are pleased to assist medical device manufacturers in their quest to design innovative products that improve health and well-being. In this case, supporting Nexxt Spine with MTS material test systems that are helping them find better ways to repair spines and improve quality of life for spine surgery patients.