The George E. Brown, Jr., Network for Earthquake Engineering Simulation (NEES) is a national, networked seismic simulation resource that serves a geographically distributed network of experimental research sites, including the University of Colorado (CU) at Boulder. NEES strives to accelerate the science of seismic engineering, with the ultimate goal of optimizing the performance of civil and mechanical infrastructure systems.

CUSTOMER CHALLENGE

Historically, earthquake engineers have been forced to choose between two methods for evaluating the performance of a structural system under earthquake loads:

1. Employment of a large seismic simulator, or shake table, to physically shake the

entire structure

2. Pseudodynamic testing, which uses multiple actuators to apply force and motion

to specific portions of a structure

Using a seismic simulator provides a realistic response rate for evaluating vibration dynamics. However, many test labs consider mounting a full structure on a shake table cost-prohibitive, due to the significant time and expense required for setup. In addition, structures that can be tested are limited by the size and payload capacities of the test equipment.

Pseudodynamic testing, on the other hand, costs less and is capable of testing much larger structures than a seismic simulator, but it applies forces and motions at a slower rate than would be experienced in an actual earthquake event. In fact, the rate of loading is often 100 times slower than the actual real-time response rate of the structure to an earthquake. As a result, while pseudodynamic testing is a good tool for measuring structural strength and stiffness, it cannot sufficiently evaluate dynamic properties, which are essential to assessing a structure’s seismic performance. To date, most hybrid simulation systems have been based on pseudodynamic testing.

MTS SOLUTION

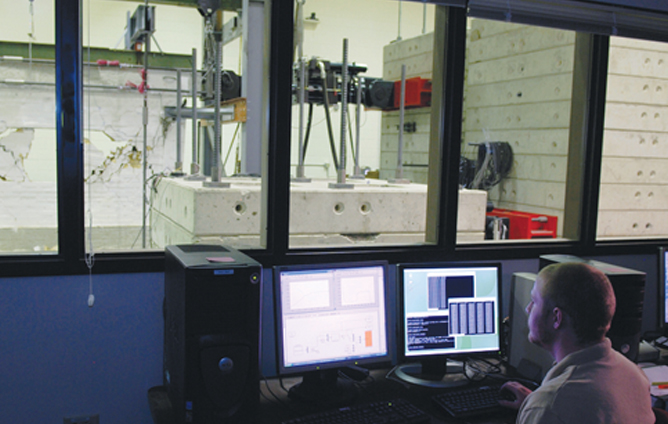

NEES at CU-Boulder collaborated closely with MTS to develop a state-of-the-art Fast Hybrid Testing (FHT) system, designed to physically test a substructure, while computer models digitally simulate the physical influence of the structure surrounding the substructure. This real-time hybrid simulation technology combines the strengths of virtual and physical testing to yield unprecedented speed, accuracy and cost-efficiency.

The modeled and physical tests are tightly coupled and operate at 1024 Hz, which enables the accurate evaluation of vibration dynamics in addition to strength and stiffness testing. Typical subjects for Fast Hybrid Testing include structures such as shear walls and bridge columns, and components such as base-isolation systems and response-mitigation devices.

Comprised entirely of MTS hardware and software, the FHT system features three high-speed, high-capacity actuators driven by an MTS controller linked via a highspeed interface into a real-time computer simulation application. The system also features online access to an array of data management and sharing tools, enabling seismic engineers at CU-Boulder to collaborate with peer researchers at remote NEES locations.

MTS also helped NEES develop the necessary algorithms to support realtime hybrid simulation. “The actuators can’t achieve this rapid response rate by themselves,” said NEES site manager Tom Bowen said. “Rather, they have to be told what to do, and MTS was instrumental in developing the necessary computational capabilities to drive such speed.”

“Real-time, or fast hybrid simulation is made possible by today’s fast computer processing capabilities, which can apply the advanced algorithms necessary to reconcile physical testing and virtual modeling data into a single simulation,” said Bowen. “But most significantly, this testing occurs at a rate approaching the real-time response of a structure under actual earthquake loads. That means you get the cost-efficiency of pseudodynamic testing, along with a highly realistic response rate that could formerly only be achieved using a shake table.”

CUSTOMER BENEFITS

According to Bowen, NEES chose to use MTS hardware, software and consultative support for the project, due to MTS’ seismic testing leadership, the breadth of its product offering and its reputation for unmatched after-sale support.

“We asked ourselves what would be required in equipment and expertise to create a real-time hybrid system, and MTS repeatedly rose to the top,” said Bowen. “The MTS proposal came in a bit higher than others, but we chose to work with them because the value delivered by their solution extended well beyond the others. This is an excellent testimony coming from a state university that is primarily driven by budget.”

Enhanced Seismic Testing for Labs Across the US

Researchers across the country have access to CU-Boulder FHT solution through the NEES network. Tests can be run either onsite in Boulder, or distributed remotely via the Internet. The FHT system significantly enhances seismic testing by making the high loads and real-time response rates of an actual earthquake event available to a broader community of test labs. The system is a cost-effective alternative to a shake table, technologically superior to traditional pseudodynamic testing, and it allows for the improved understanding of complex coupled systems.

The virtual models created with the FHT system also save engineers valuable time when conducting their own tests on substructures and components.

“In addition to providing more robust test data,” said Bowen, “the FHT system allows seismic engineers to spend more time researching and less time worrying about how to support their testing initiatives. It permits the open exchange of information across the entire community. We’re all drawing from a collective level of expertise that is not available at any one test lab, and the entire industry is benefiting from it.”

Bowen said that a key ingredient to the FHT program’s success was their partnership with MTS. “I know this term gets overused, but MTS was a partner to us in the truest sense,” he said. “There have been no limits to the expertise and support MTS has provided.”