CUSTOMER CHALLENGE

The University of Central Florida (UCF) in Orlando has earned a reputation for high-quality education and innovation since its founding in 1963. During this time, the university’s Department of Mechanical, Materials & Aerospace Engineering has forged strong alliances with several world-class manufacturers and organizations located in the area, including Siemens Power Generation, Lockheed Martin, Pratt & Whitney, Mitsubishi Power Systems and even the Kennedy Space Center.

In addition to furnishing a steady supply of well-prepared engineers to these organizations, the department has become valued for working closely with them to resolve their technical challenges.

To further its dual mission of providing a superior education and supporting local industry, UCF wanted to add high-temperature materials testing to its core capabilities. Developing such capabilities would enhance the learning experience for students, and it would benefit the department’s partners in local industry who manufacture products designed to perform at extremely high temperatures.

In 2006, UCF brought Dr. Ali P. Gordon on board, as both a teaching professor and to oversee the development of high-temperature material testing capabilities. As a graduate student at Georgia Institute of Technology, Gordon’s studies focused specifically on characterizing the behavior of turbine blade materials at high temperatures. This experience made him an ideal candidate for pushing the department’s materials testing to the next level.

“The department’s interest in strengthening its experimental mechanics in both the laboratory and in the classroom immediately appealed to me,” Gordon said. “And it was clear that the pieces were in place at UCF to build one of the country’s top mechanical behavior of materials research and test facilities. I was eager to get started.”

Developing the department’s high-temperature mechanical testing capabilities would require the acquisition of load frames, controls, software, and numerous accessories. From past experience, Gordon knew the real challenge would lie in getting all these components to work together seamlessly.

“Effective materials testing in extreme service conditions involves precise orchestration of force, motion, data acquisition and environmental simulation, which can be very difficult to achieve from a configuration perspective,” Gordon said. “So when sourcing a test solutions partner, we sought someone that could offer both proven technology and advanced systems integration expertise. That’s why we chose MTS.”

MTS SOLUTION

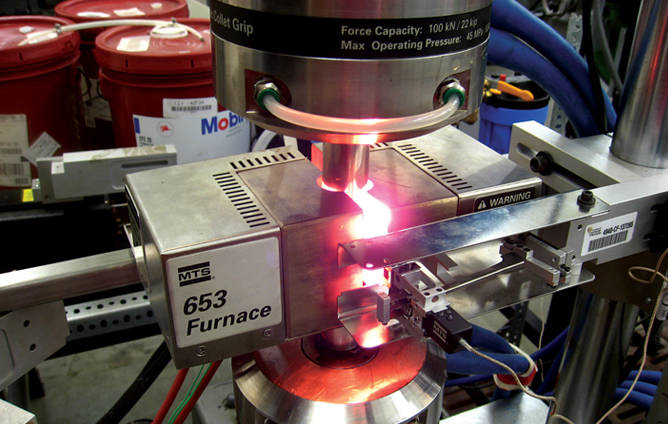

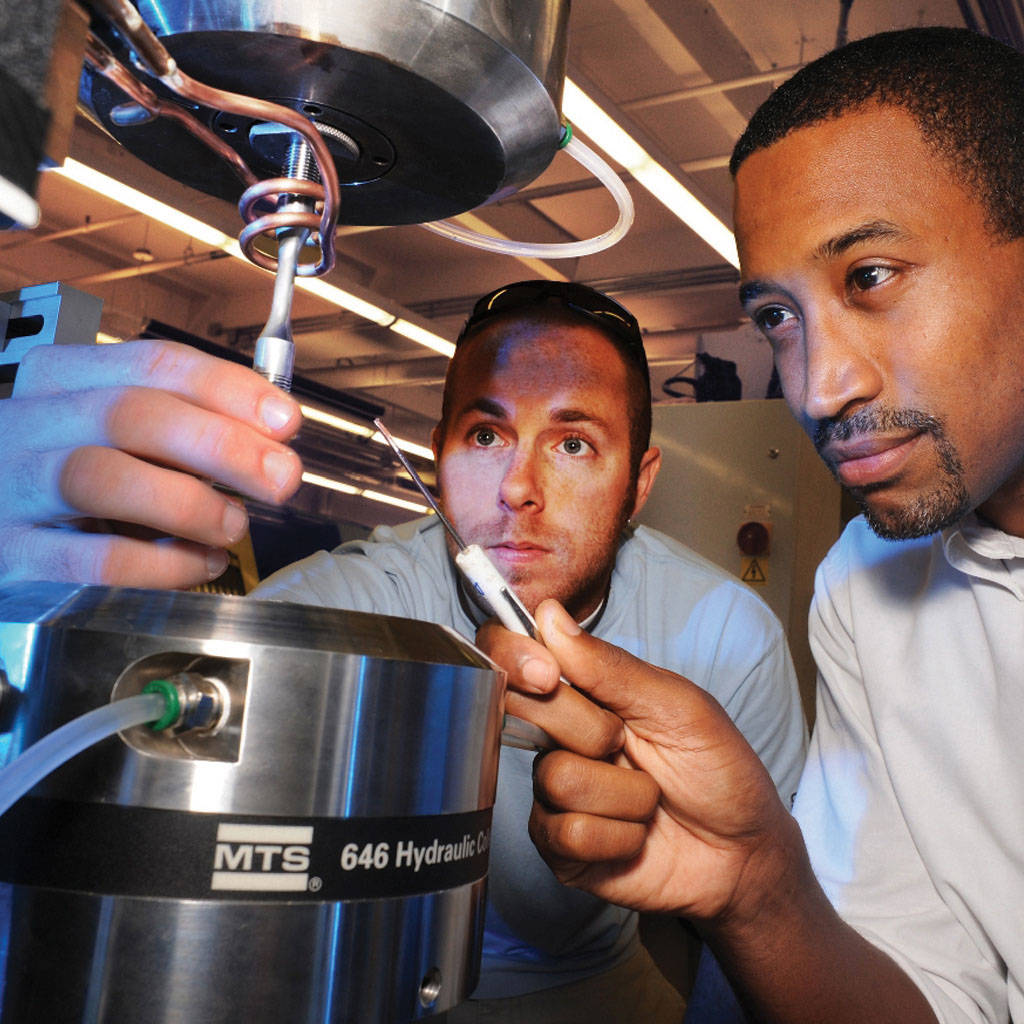

In December 2006, MTS began working with Dr. Gordon to develop high-temperature materials testing capabilities for the UCF Department of Mechanical, Materials and Aerospace Engineering. This required the integration of the department’s existing mechanical test system, which comprised a Model 810 servohydraulic load frame, TestStar IIs controller and Multi-Purpose TestWare® software, with an array of high temperature environmental simulation components, including an MTS resistance heater, Model 646 water-cooled hydraulic wedge grips, and a high-temperature axial extensometer capable of maintaining high linearity and low hysteresis at temperatures up to 1200° C.

The newly upgraded system enabled Gordon’s department to run a full battery of high temperature testing tests to support its research, its students and the local industry. “Our new system effectively extended our mechanical testing capabilities to include fatigue, fracture, creep-fatigue, low-cycle fatigue, thermomechanical fatigue, tensile loading, and stress/relaxation testing - all in very high-temperature environments,” he said.

Gordon cites two examples of how his department is applying its new high-temperature testing capabilities to better serve its industry partners. “As part of our relationship with Siemens, we’re currently subjecting steel materials for a land-based steam turbine to thermal and mechanical strains simultaneously, at temperatures cycling between 100° C and 500° C,” he reported. “Additionally, we’re helping the Florida Center for Aerospace & Aero- Propulsion (FCAAP) Technologies study how components with notches respond to non-isothermal fatigue conditions, again at 500° C. Both applications are shedding valuable new insight on the micro-structural damage mechanisms that these components sustain under service conditions.”

Gordon says that he was pleased that his group’s MTS test solutions are not limited to high temperatures – or even thermal exposure – alone.

“We are also working with the Office of Naval Research (ONR) to study the phenomenon of stress corrosion cracking (SCC). Specifically, we are studying the time-dependence of early crack extension of aluminum with liquid metals, such as Hg, in close proximity,” Gordon said. “And engineers from NASA and United Space Alliance, LLC, are using our capabilities to study the creep-relaxation response of gasket materials. These tests are run at room temperature now, but we’re considering adding a chamber or other device to simulate the extremely low-temperatures of space-based conditions.”

“No matter what aggressive environments we need to replicate, we are confident that the MTS technology is versatile enough to help us develop the simulated environment,” he added.

CUSTOMER BENEFITS

According to Dr. Gordon, the expanded material characterization capabilities at the UCF Department of Mechanical, Materials & Aerospace Engineering hold tremendous benefits for students, the College of Engineering and Computer Science, and the university’s commercial partners alike.

“We are now able to shed more light on how advanced materials behave under extreme service conditions,” Gordon said. “These capabilities are allowing us to dig deeper than ever into materials science, and it is allowing the businesses we work with to develop more accurate component behavior prognostics tools.”

Gordon stresses that while his department’s testing capabilities are sophisticated, the tools for creating the running the tests are relatively simple to understand and use. This is an especially useful benefit for UCF engineering undergraduates in experimental mechanics laboratory courses. “The MTS software’s simple user interface and visualization tools make it easy to grasp even advanced concepts, especially for fatigue and fracture applications,” Gordon said. “Our equipment upgrade has clearly enriched the learning experience for our students.”

Gordon also cites MTS people as a crucial element to his lab’s enhanced testing capabilities. “It has been a pleasure working with MTS, especially the technical support staff,” he said. “I knew from experience that MTS testing technology is the most reliable on the market. Now I know firsthand that this reliability also extends to its service personnel.”