David Ferguson, MTS Mechanical Engineer, shares his non-ambient testing expertise in this high-temp testing Q&A where he outlines basic testing challenges and describes his experience working with MTS’ high-temp testing solutions.

Q: What happens during a high-temperature test?

A: Essentially, the objective is to get things really hot, and then maintain that high temperature on the test specimen while making sure the testing components don’t get too hot. You’re doing all of this as you are running the material tests and trying to collect accurate data … sounds simple right?

Q: Why do researchers conduct high-temp testing?

A: With all the recent interest in aerospace applications, the market seems to want to test materials at hotter and hotter temps, which is creating new challenges. Researchers need to test materials intended for use in things such as aerospace turbine blades or spacecraft components at these higher temperatures to understand how they would respond to real-world loading and conditions. Typical tests include tension, compression, bend and fatigue for metals, composites, ceramics and more.

Q: What are some of the challenges in high-temperature testing?

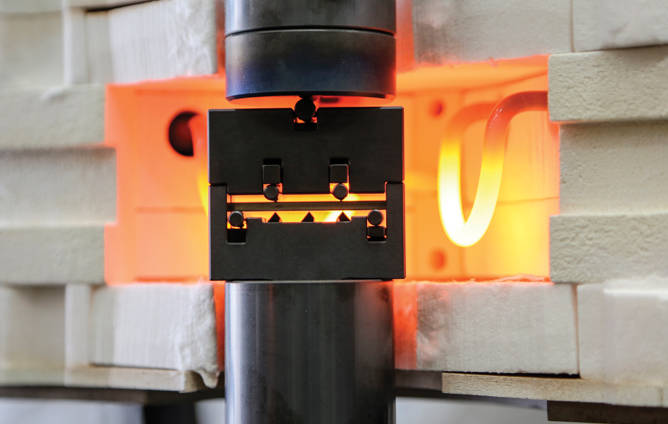

A: The main challenge is temperature—who would’ve guessed? Not only do you need to be able to reach a certain temp with your furnace, chamber or induction heating equipment, but you also need to make sure that the grips, fixtures and extensometers can withstand the testing temperatures without compromising their strength. Many materials used in manufacturing these testing accessories have very different characteristics at higher temps, so we incorporate water-cooling or air-cooling methods to keep these components within an ideal temp range. Managing the temperature of the accessories during the test also increases their service life.

Another challenge is controlling the temperature gradient that the testing specimen experiences. You want uniform temperature distribution throughout the top, middle, and bottom of specimen, and this can be difficult to achieve in some instances, especially when using cooled grips. Accurate testing requires a uniform temp gradient, so we use thermocouples to gauge the temp of the specimen at different points on the sample to control the temperature output of the furnace.

Q: What solutions does MTS provide for high-temp testing?

A: In addition to robust load frames, MTS offers multiple heating methods like furnaces, chambers, and induction heating. The application and test type dictate the heating method as well as other aspects of the testing system. We also offer many types of grips for various sample types. Whether it is a flat, round or threaded sample, we have a grip for it. Grips can be mechanical, hydraulic or pneumatic depending on test type and customer preference. We have high-temp extensometers and software templates too. And, of course, we have engineering consulting expertise in high-temp applications.

Q: Has anything surprised you about working with MTS test solutions?

A: MTS has allowed me to design, invent, innovate, calculate … be an in-depth engineer. I’ve been impressed with the high degree of complexity and detailed engineering that goes into these machines. I never thought I would have a discussion regarding the speed of sound through metals but those are the kind of details we go into.

What surprises me most is the extent MTS will go to make an application work. MTS has the capability and experience to find a solution that can meet challenging customer requirements. Along with that, I am just fascinated by the things we work on and what they will be used for. Knowing I work on machines that test metals or composites that are going to be on rocket ships is an awesome feeling and making a system for someone testing a novel material that could be used to revolutionize the world is pretty cool.

Q: In your opinion, what is the primary advantage of using MTS’ high-temp testing solutions?

A: The ability to deliver reliable, repeatable, high-quality data. Everything starts at the specimen, and we design systems that run intense tests that give you accurate data on the material you are testing. At the end of the day, it’s all about having quality data that you can trust.