Conducting cyclic strain controlled tests in the elastic-plastic region at elevated temperatures requires extremely stable and precise test system control. MTS offers a complete solution set for accurate high-temperature, low-cycle fatigue (LCF) testing of metal, ceramic and composite materials.

|

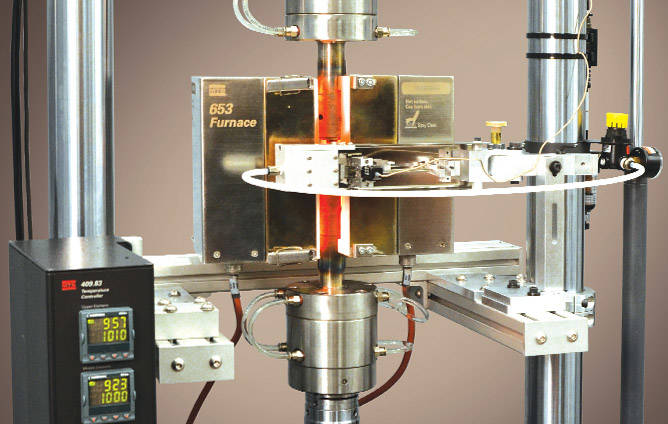

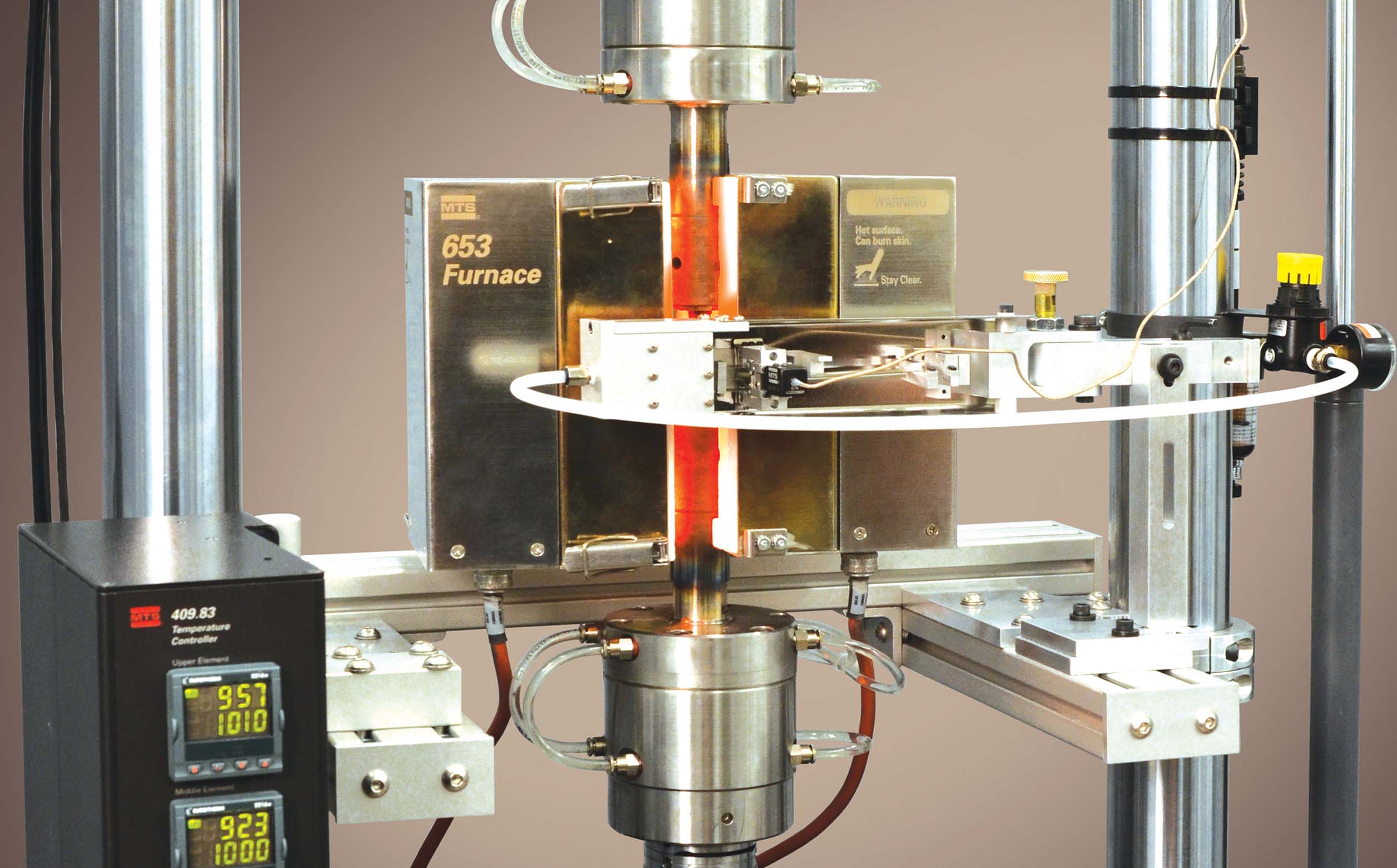

MTS Landmark Load Frames & High-Temp Furnaces MTS Landmark Test Systems feature a highly stiff load frame design that minimizes specimen buckling under high compressive strains. Also superior system alignment minimizes bending strain to maximize accuracy and reduce data scatter. Model 653 High-Temperature Furnaces are ideal for a wide variety of high-temp tests, including tension, compression, bend and fatigue testing of metals, composites, ceramics and many other materials. They help operators set up more quickly without compromising test quality or accuracy. |

|

|

High-Temp Grips Model 680 High-Temperature Grips were expressly designed for high-temperature, low-cycle fatigue testing, but can also be used for other types of tension-compression or tension-only testing. The grip heads and extension rods are made of superalloys that can extend into the heated zone of the furnace, minimizing the thermal gradients within the specimen. |

|

|

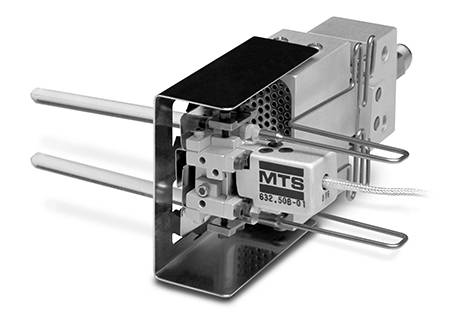

High-Temp Extensometers The air-cooled Model 632.50 High-Temperature Axial Extensometer measures axial strain in high temperature tension, compression, and through-zero fatigue testing applications up to 1200°C (2200°F). Water-cooled extensometers or low-strain extensometers are also available for high-temp applications. |

|

|

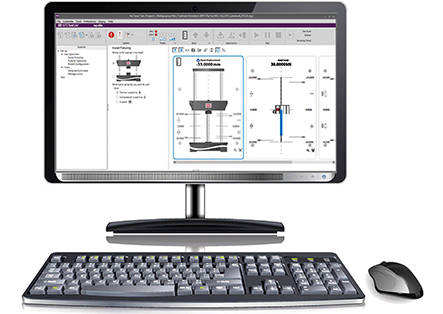

MTS TestSuite™ Software & Advanced LCF Module The Advanced LCF Module for MTS TestSuite Software includes the calculations, test templates and report templates needed to run constant-amplitude, strain-controlled fatigue tests. The module is also designed to calculate and correct for thermal expansion during non-ambient testing, and includes a custom waveform activity for efficiently defining arbitrary waveforms, including user-defined hold times. You can: |

|