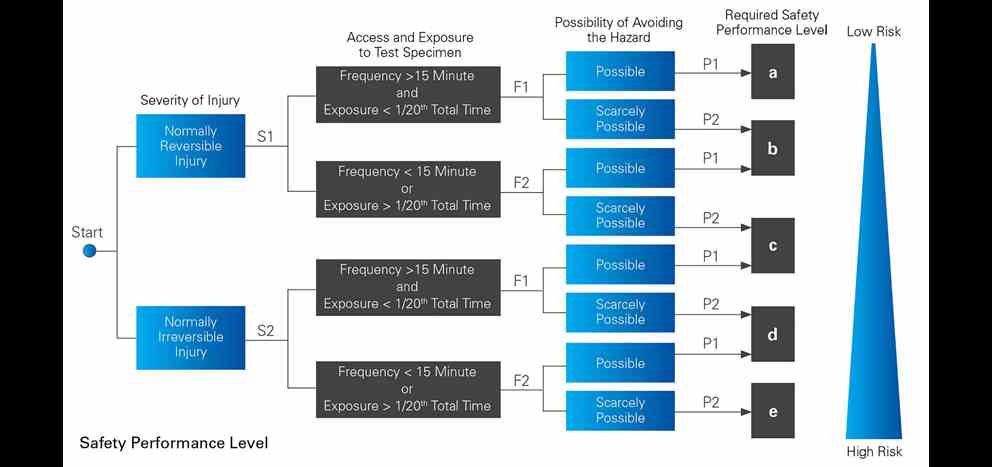

All organizations strive to provide a safe working environment, yet there is still a great deal of confusion about best practices and compliance requirements for safe operation of machinery. ISO 13849 offers clear guidelines about potential human safety risk and the required Safety Performance Level for each situation. This international standard is a common end-user requirement in the EU and is referenced in many other regional safety standards.

Three factors influence the required Performance Level:

1. Potential severity of injury

2. Frequency of exposure

3. Possibility of limiting the hazard

SEVERITY OF INJURY

Slight or Serious

The two options for classifying equipment in the severity of injury category are: slight, indicating a normally reversible injury; and serious, indicating a normally irreversible injury or death. Due to the potential for irreversible injury or death when operating test equipment, mechanical test systems are in the serious classification, which requires a minimum of Performance Level c (PLc) for compliance.

FREQUENCY AND/OR DURATION OF EXPOSURE

Seldom or Frequent

For test equipment, the frequency of exposure is defined as access to the specimen area. Access typically occurs in specimen loading, unloading, adjustment and alignment. With respect to exposure time, “seldom” is defined as accessing the specimen area no more than once in 15-minute intervals and the accumulated exposure time does not exceed 1/20 of the overall operating time. In this circumstance, the rating would be “F1” for exposure. If the test operator is accessing the specimen more than once every 15 minutes or this exposure exceeds 1/20 of the overall operating time, it is considered frequent exposure, or an “F2” rating for exposure. Frequent exposure of an “F2” rating requires a minimum Performance Level d (PLd) for compliance. Seldom exposure could require a Performance Level of c or d, depending on the possibility of avoiding or limiting the hazard

POSSIBILITY OF AVOIDING THE HAZARD

Possible or Scarcely Possible

There are two categories for possibility of avoiding the hazard or limiting the harm: possible under specific conditions or scarcely possible. A risk assessment can help determine the appropriate category. If there is a use case in which the possibility of avoiding the hazard is considered scarcely possible and severity = S2, then this case would require a minimum of Performance Level d. If in this same case, the frequency of exposure = F2, then it would require a Performance Level e solution.

FREQUENCY OF TEST SPECIMEN AREA ACCESS IS A CRITICAL FACTOR

In summary, a Performance Level rating of c, d or e is required to meet certain safety standards for most test equipment. Frequency of access and exposure to the test specimen area are the primary factors in determining the required safety performance level. Contact MTS today to discuss your safety requirements.