Elastomer Test Systems

Apply precise single- or multi-axial linear and rotational forces to elastomeric materials and components to ensure quality and optimize performance and durability. The diverse MTS portfolio features advanced application software and controls and the industry’s largest force and frequency range to maximize elastomer testing accuracy, repeatability, and efficiency.

Applications

- Dynamic Characterization

- Dynamic Mechanical Analysis (DMA)

- Static Deflection

- Durability

- Quality Control

Test Specimens

- Materials

- Bushings

- Engine Mounts

- Transmission Mounts

- Damper Top Mounts

- Vibration Attenuation or Control Elements

Key Product Features

Global Standard

The industry's widest range of force and frequency capabilitiesfor R&D or QA/QC applications of materials and components

Reliable Data

Superior Test systems integrating accurate and repeatable measurements yield data that you can trust

Real-World Correlation

From simple sine waves to real-time simulations . . . and of course, everything in between

We Can Help

We support OEMs and researchers through the most challenging test objectives, saving them time and money

Model Comparison

Model 836

- Force: 25 kN

- Frequency: 80 Hz

- Controlled Axes: 6

- Typical Applications:

Durability

Model 834

- Force: 50, 100, 150, 250 kN

- Frequency: 200 Hz

- Controlled Axes: 1

- Typical Applications:

High-force Durability

Model 833

- Force: 25 kN

- Frequency: 80 Hz

- Controlled Axes: 3

- Typical Applications:

Durability

Dynamic Characterization

Model 832

- Force: 50 kN

- Torque: 565 Nm

- Frequency: 100 Hz

- Controlled Axes: 2 or 3

- Typical Applications:

Durability

QA/QC

Model 831 Biaxial

- Force: 10, 25 kN

- Static Side-load: 5 kN

- Frequency: 800 Hz

- Controlled Axes: 2

- Typical Applications:

Durability

Dynamic Characterization

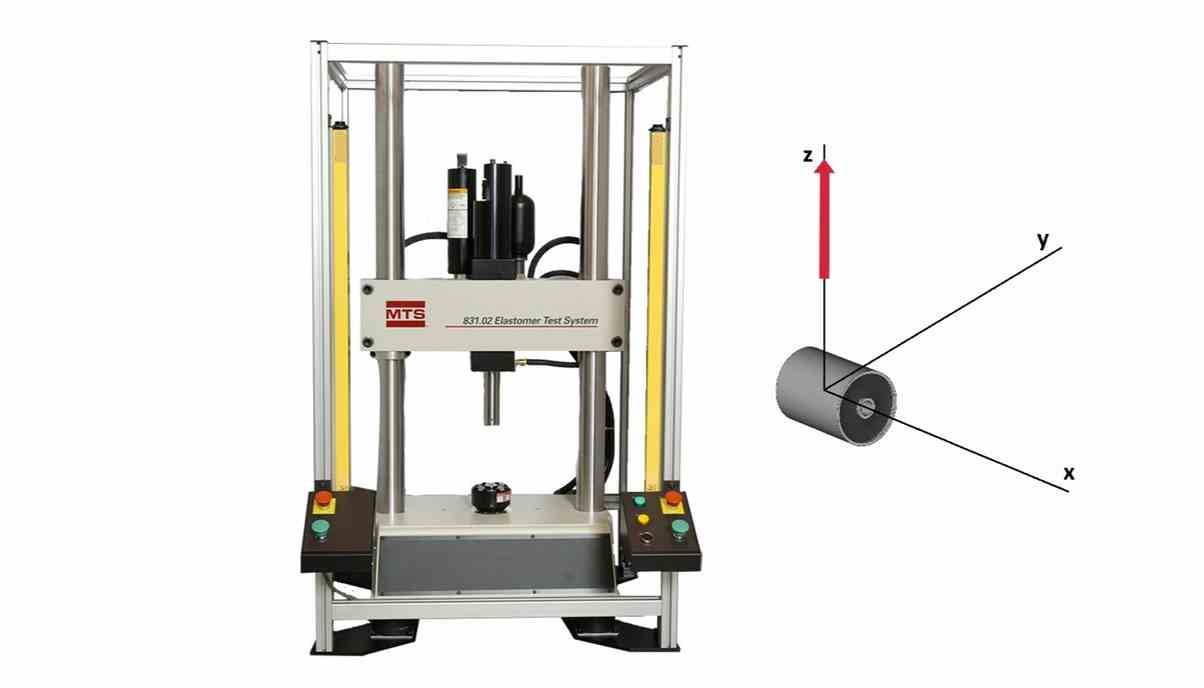

Model 831

- Force: 10, 25 kN

- Frequency: 400, 700, 1000 Hz

- Controlled Axes: 1

- Typical Applications:

Durability

Dynamic Characterization

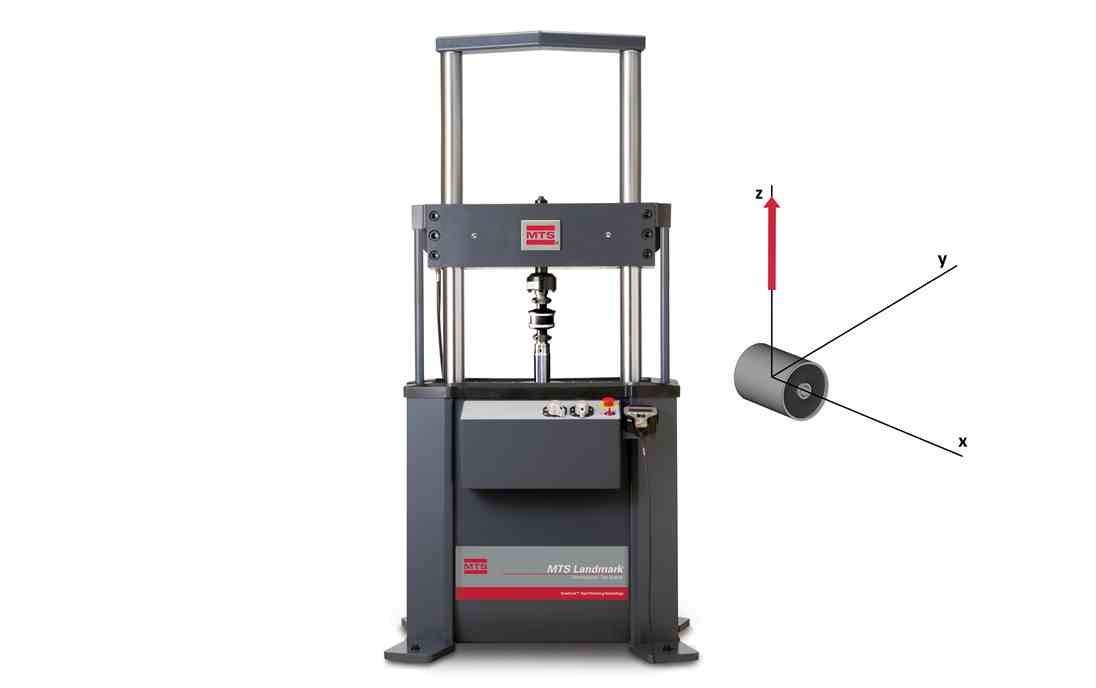

MTS Landmark 200

- Force: 10, 25 kN

- Frequency: 200 Hz

- Controlled Axes: 1

- Typical Applications:

Durability

Dynamic Characterization

MTS Landmark 100

- Force: 10, 25 kN

- Frequency: 100 Hz

- Controlled Axes: 1

- Typical Applications:

Durability

Dynamic Characterization

QA/QC

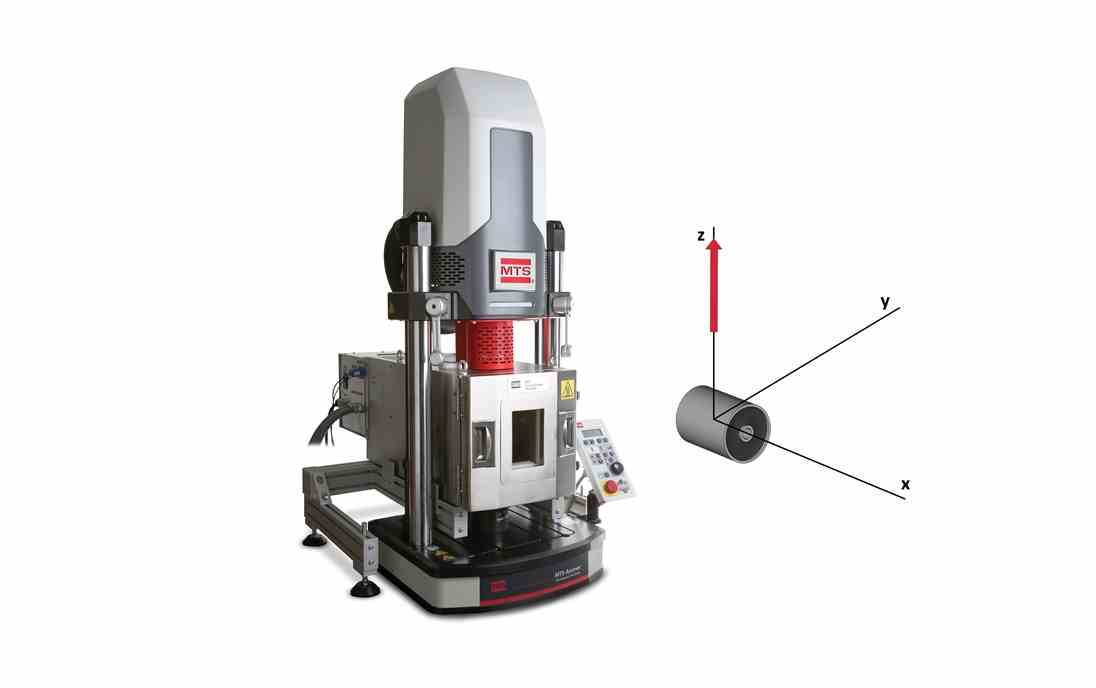

MTS Acumen

- Force: 1, 3, 12 kN

- Frequency: 100 Hz

- Controlled Axes: 1

- Typical Applications:

Durability

Dynamic Characterization and DMA

C-frame System

- Force: 15 kN

- Frequency: 20 Hz

- Controlled Axes: 1

- Typical Applications:

Durability

QA/QC

Technical Overview

Use the Model 836 to conduct realistic, accurate durability testing in six degrees of freedom.

- Low-friction actuators mounted within a compact, stiff, self-reacting base provide high-fidelity control and bandwidth

- Superior control compensation ensures data integrity and repeatability

- Perform multiple tests on the same machine without changing the setup

- Quickly install and remove test articles with the easy-access mounting assembly

Primary Applications

- Durability Testing

|

|

||

|

Fx |

kN |

25 |

|

Fy |

kN |

50 |

|

Fz |

kN |

50 |

|

Mx |

kNm |

2 |

|

My |

kNm |

12 |

|

Mz |

kNm |

12 |

|

|

||

|

X |

± mm |

25 |

|

Y |

± mm |

25 |

|

Z |

± mm |

25 |

|

Theta x |

± deg |

15 |

|

Theta y |

± deg |

5 |

|

Theta z |

± deg |

5 |

Model 836 System Brochure

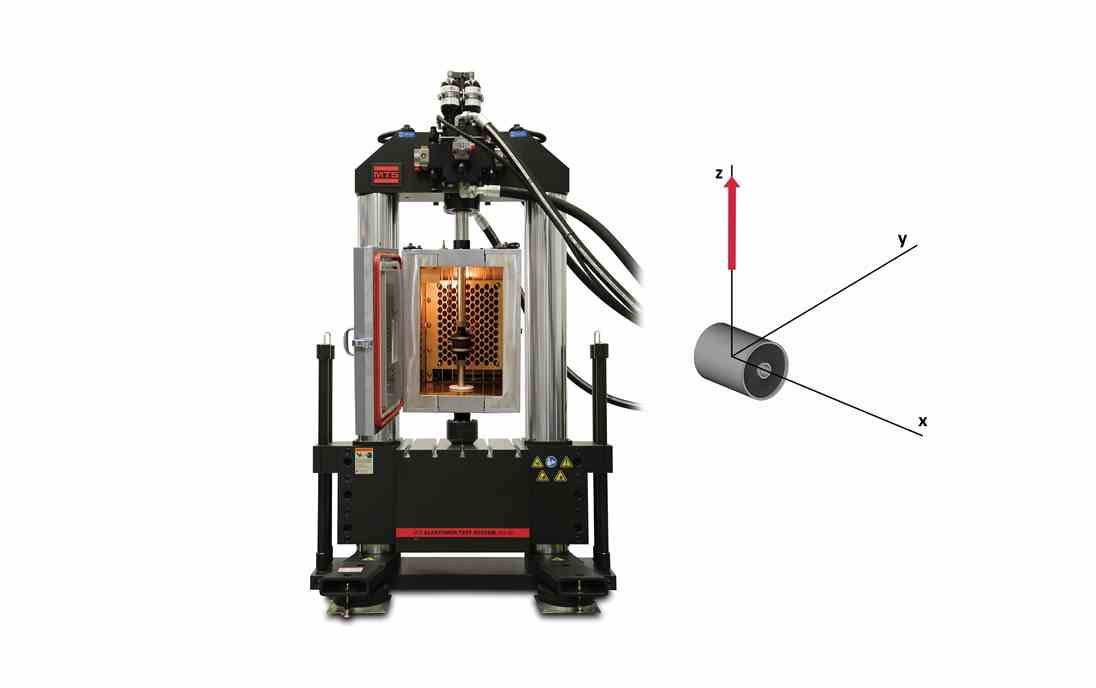

Use the robust Model 834 High-Force Elastomer Test System to test a variety of elastomeric materials, components, and mounts used in high load applications.

- Apply forces up to 100 kN at frequencies up to 300 Hz (50 kN, 150 kN, 250 kN frame ratings also available)

- Superior control compensation ensures data integrity and repeatability

- Versatile T-Slot Bed

- Shown with MTS Model 651.06E-03 Environmental Chamber: A complete integrated subsystem for performing tests in the temperature ranges of -129 degrees C to +315 degrees C.

Typical Applications

- Durability Testing

- Typical applications include trucks, construction, forestry, agricultural equipment, railway cars and aerospace

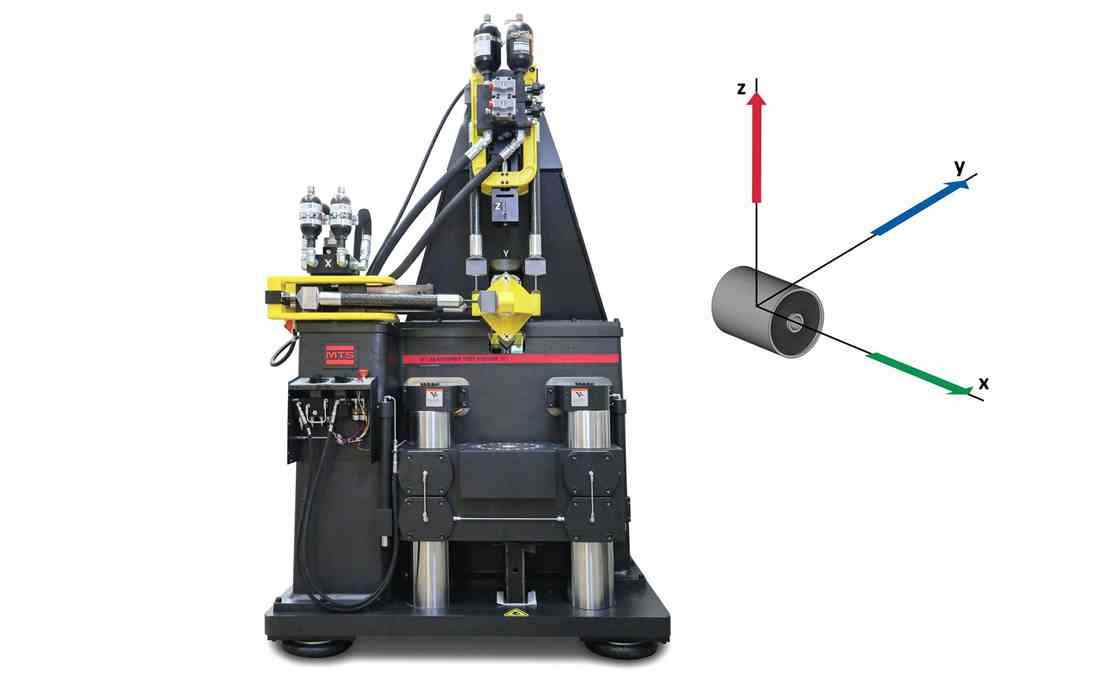

Use the Model 833 system to conduct dynamic characterization and durability testing in three degrees of freedom.

- Automated control compensation ensures data integrity and repeatability

- Designed to minimize stiffness variations as a function of frequency

- Achieve close to zero phase angle using an MTS patented control algorithm

- Test specimens up to 400 mm diameter and 550 mm tall - with or without a chamber

Primary Applications

- Dynamic Characterization

- Durability Testing

|

|

||

|

Fx |

kN |

25 |

|

Fy |

kN |

25 |

|

Fz |

kN |

25 |

|

|

|

|

|

|

||

|

X |

± mm |

25 |

|

Y |

± mm |

25 |

|

Z |

± mm |

25 |

Mx, My, Mz outputs provided for moment monitoring

Model 833 system Brochure

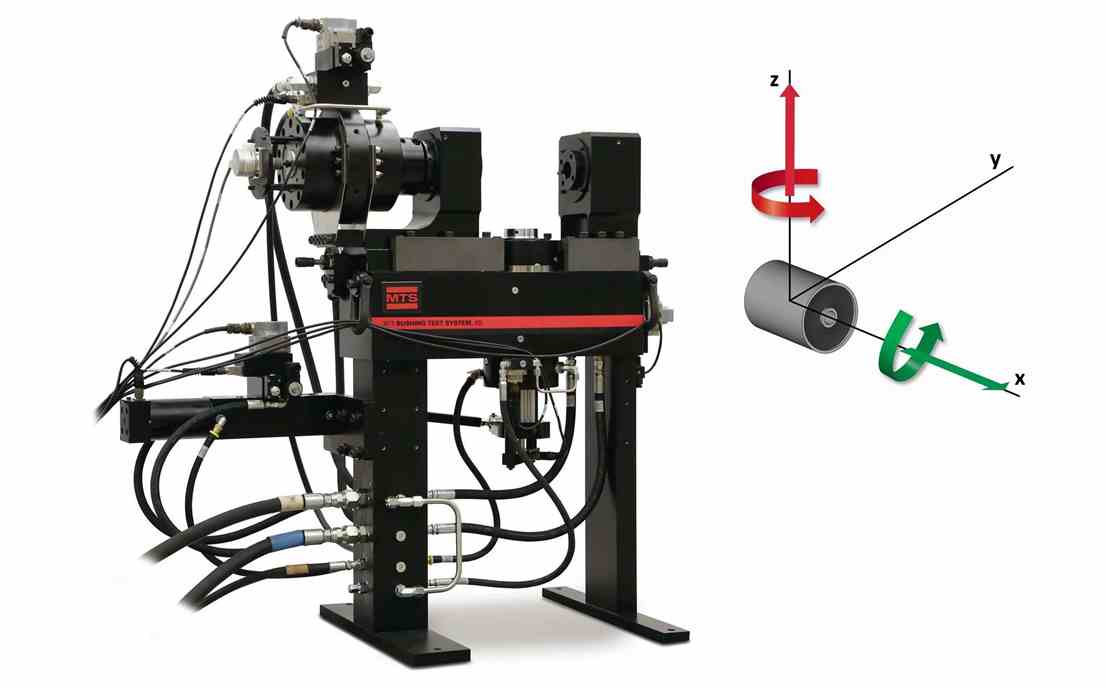

Use the Model 832 System to qualify bushing service life or conduct dynamic torsional characterization tests

- Configurable in 2-4 degrees of freedom

- Dynamic radial and torsional inputs with static offset about the bushing axis

- Increase system utility with optional hardware for dynamic inputs - conical and cardonic rotation about the radial axis or static conical input about the normal axis

- Single Axis Torsional Characterization Package includes MTS Model 663 torque transducer rated to +/- 550 Nm and MTS 793.31 Dynamic Characterization Software

- Multi-Axis Configuration: Static Conical about Normal Fixture imparts 10 degrees static conical offset to the bushing

- Anti-rotate about Radius Axis prevents undesired rotation of the vertical actuator

Primary Applications

- Durabilty Testing

- Dynamic Torsional Characterization (x-axis)

|

Load Capacity (non-simultaneous) |

|

|

|

Fx (static) |

kN |

4.4 |

|

Fz |

kN |

50 |

|

Mx |

Nm |

565 |

|

Mz |

Nm |

678 |

|

|

|

|

|

Range of Motion (non-simultaneous) |

|

|

|

x |

± mm |

10 |

|

z |

± mm |

5 |

|

Theta x (dynamic) |

± degrees |

45 |

|

Theta z (static) |

± degrees |

22 |

|

Theta z (dynamic) |

± degrees |

19 |

Model 832 System Brochure

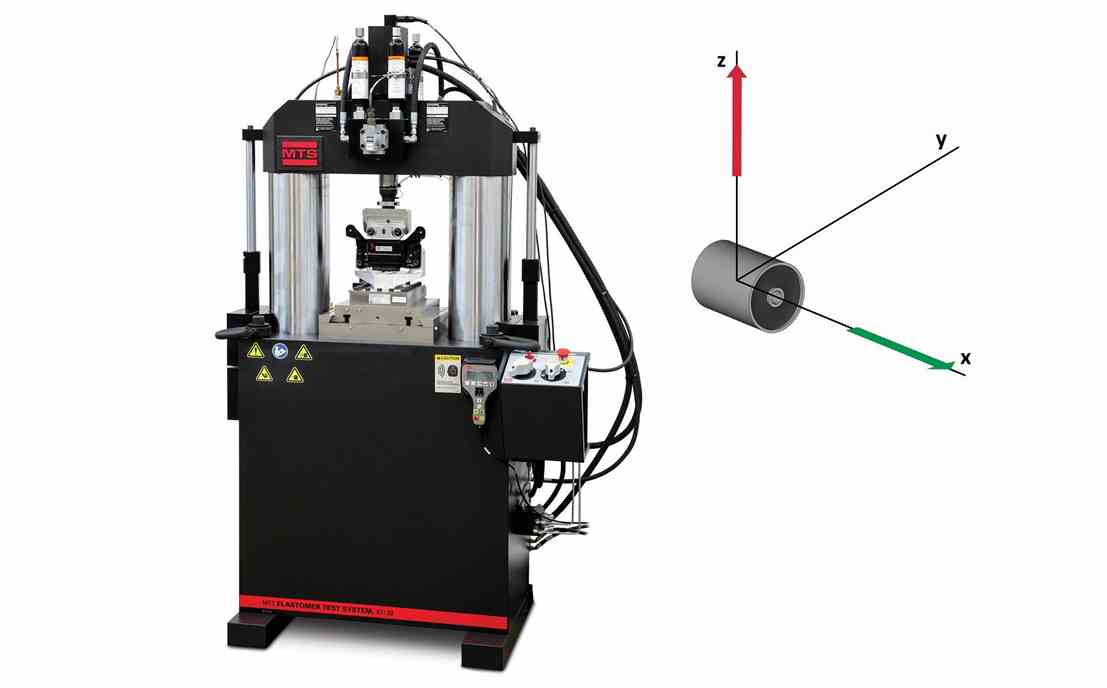

Characterize materials and components at high frequency with static pre-load in off axis.

- Massive, robust and reliable design engineered for high frequency operation and low force/displacement resolution.

- Acceleration compensation is built into the force measurement system.

Primary Applications

- Materials Research

- Component Development

|

|

||

|

Fz (800 Hz) |

kN |

25 |

|

Fx (Static) |

kN |

5 |

|

|

||

|

Z |

± mm |

25 |

|

X |

± mm |

15 |

Mx, My, Mz outputs provided for moment monitoring

Characterize materials and components at medium to high frequency.

- Dedicated models available to meet your test frequency requirements.

- Acceleration compensation is built into the force measurement system.

Primary Applications

- Materials Research

- Component Development

|

|

||

|

Fx (400 Hz) |

kN |

10/25 |

|

Fx (700 Hz) |

kN |

25 |

|

Fx (1000 Hz) |

kN |

10 |

|

|

||

|

Static Stroke |

± mm |

25 |

|

Dynamic Stroke |

± mm |

20 |

From the Landmark family of universal test machines, specifically configured for accurate, resonant free testing to 200 Hz.

- Force capacities of 15 kN or 25 kN.

- Free-standing, self-supporting unit that requires no special foundation.

Primary Applications

- Materials Research

- Component Development

- Universal Tensile & Compression Testing

From the Landmark family of universal test machines, specifically designed for requiring minimal space.

- Force capacities of 15 kN or 25 kN

- Resonant free testing to 100 Hz.

- Table Top Model lending itself to be integrated into automated test environments

Primary Applications

- Materials Research

- Component Development

- End-of-line Production Testing

- Universal Tensile and Compression Testing

From the MTS Acumen family of electro-dynamic test systems, specifically designed for elastomer testing.

- Force capacities of 1, 3, and 12 kN

- Minimal facility requirements due to electric actuation

Primary Applications

- Materials Research

- Component Development

- End-of-line Production Testing

- Universal Tensile Compression Testing

MTS Elastomer Testing Solutions are commonly provided with a complete integrated sub-system for performing tests with temperatures ranging from - 40 deg C to +150 deg C (- 40 deg F to +300 deg F). Temperatures for these system are programmable from the FlexTest workstation and typically feature:

- Insulated chamber – frame-mounted with hinged door

- Windowed door for test article viewing during test

- Mechanical refrigeration with liquid nitrogen boost capability

- Insulated boot attached to specimen adapter for better environmental seal

- Remote mounted mechanical temperature conditioning unit connected to the specimen enclosure by large diameter insulated flexible tubes

Service and Support

Our experts are here to help keep you up and running.

Related Products, Parts or Accessories

MTS Elastomer Testing Software

FlexTest® Controllers

RPC® Connect Software

SilentFlo™ 515 & 525 Hydraulic Power Units (HPU)

Series 295 Hydraulic Service Manifolds

Looking for more products?

Go to Solution Finder