State-of-the-art 6DOF test system integrates the latest MTS mechanical, software, and controller innovations to meet industry demands for increased durability test accuracy, productivity, connectivity, and efficiency.

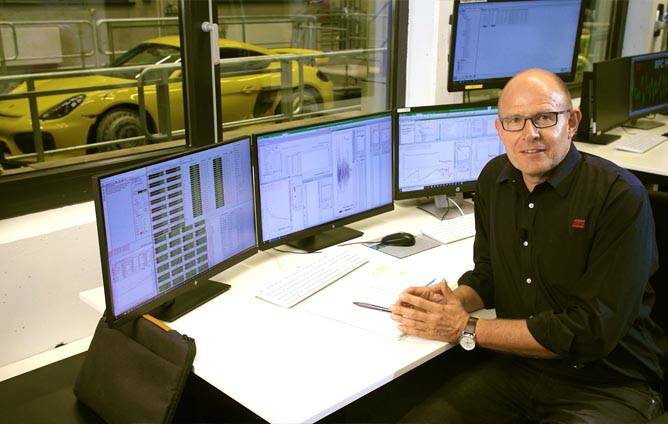

Hans-Peter Beggel - Senior Systems Engineer introduces the new Model 329i Spindle-Coupled Road Simulator, which combines a patented kinematic design, next-generation RPC® Connect software, and FlexTest® Elite Performance system controls to achieve new levels of durability test fidelity and productivity. Each corner of the road simulator is designed to apply force and motion in six-degrees-of-freedom (6DOF) through a vehicle spindle to playout field-measured or synthetic road loading, enabling test engineers to replicate the effects of real-world driving on vehicles and subsystems in tightly controlled and repeatable laboratory settings.

The next-generation 329i is purpose-engineered to achieve optimal road simulation accuracy and productivity; connect seamlessly with active vehicle systems and CAE models; and maximize test system operational efficiency, reliability, and longevity.

A patented kinematic design delivers the 80 Hz loading needed to achieve optimal road simulation accuracy and productivity, while numerous mechanical refinements and MTS DuraGlide® actuators maximize test system reliability and longevity.

Real-world road loads are defined, iterated, and played out in high fidelity using RPC Connect software, which features a new suite of simulation control, analysis, and information management tools - all designed to maximize test efficiency.

A FlexTest Elite Performance controller enables users to connect more data acquisition, monitoring, and active vehicle systems; perform more advanced calculations-in-the-loop and hybrid simulation; and achieve optimal test system rates.