Superbike manufacturer leverages new RPC Connect Software to achieve component optimization and weight reduction goals with speed and efficiency.

RPC Connect Software was combined with a single corner of a Cornering Performance Analysis System (CPAS) to subject a racing motorcycle seat support to real-world inertial forces in the test lab, providing an efficient means for gaining the highly accurate fatigue data needed for successful component design optimization - without having to test the full motorcycle.

By replicating the component fatigue process with high fidelity in the test lab, the manufacturer was able to reduce the safety coefficient for fatigue calculations and ultimately remove 80 grams of mass from the superbike seat support.

A Cornering Performance Analysis System (CPAS) can be used to apply track-measured accelerations and vibrations to full motorcycles or components in a controlled laboratory setting at tilt angles up to 60 degrees and frequencies up to 50 Hz.

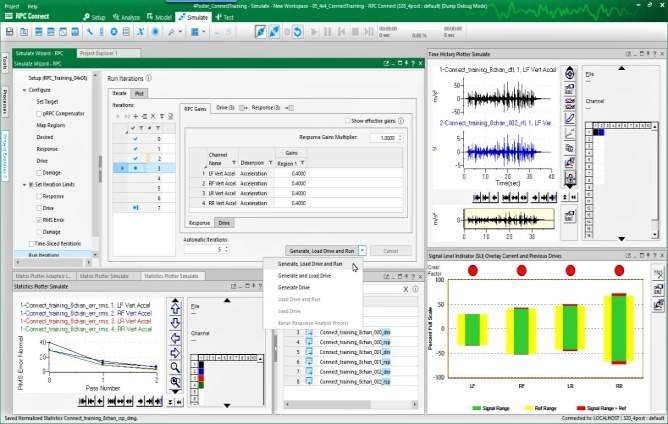

Next-generation RPC Connect Software features an intuitive new GUI and powerful array of tools and wizards to streamline durability test setup and iteration, and accelerate the acquisition of highly accurate vehicle and component fatigue data.