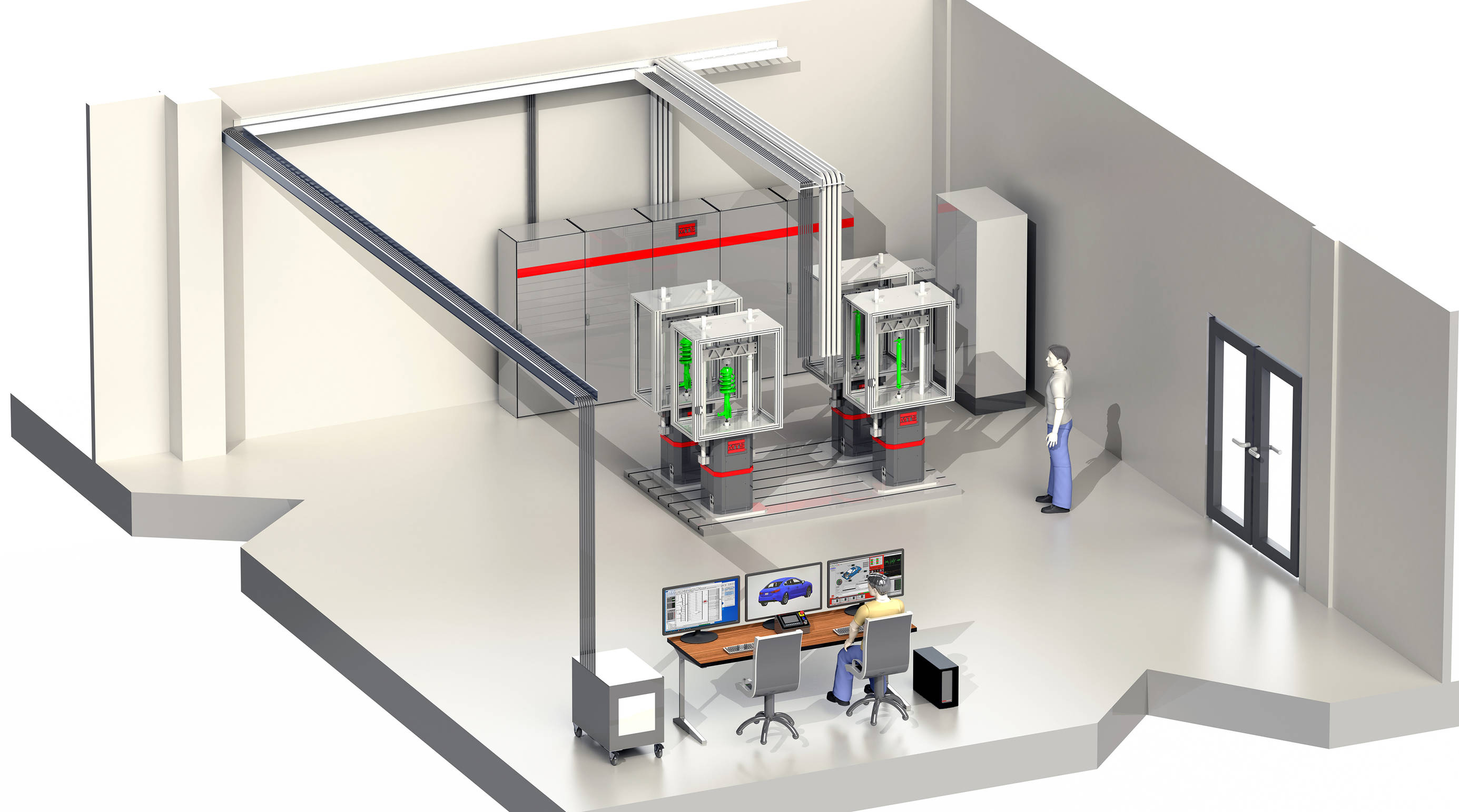

Understanding the behavior of active and semi-active damper systems poses unique challenges to vehicle developers. Using proven MTS hybrid simulation technology, the mHIL Damper Test System creates a real-time, vehicle-level simulation environment for performing meaningful evaluation of active and semi-active systems earlier in development – well before the availability of pre-production prototypes.

Ford Boone - Vehicle Dynamics Product Manager explores how MTS' proven mechanical Hardware-in-the-Loop (mHIL) technology combines computational vehicle models and physical damper test rigs in real-time to enhance CAE , provide accurate, meaningful, vehicle-level evaluation earlier in development, streamline proving ground validation and reduce the need for prototypes.

mHIL Damper Test System: Exploration & Demo

Ford Boone, Dr. Juan Garcia – Senior Staff Software Engineer, and Tom Stachel – Senior Staff Engineer provide an in-depth examination of the modeled and physical components of the mHIL Damper Test System, demonstrating how they combine to create a high-fidelity vehicle-level simulation environment.

The MTS mHIL Damper Test System enables meaningful evaluation of active and semi-active damper, suspension and body control systems earlier in development - well before the availability of pre-production prototypes and track validation.