Exceed® Electromechanical Test Systems

Systems with force capacities from 5 to 600 kN (1,100 to 132,000 lbf) meet QA/QC requirements and uptime demands of production environments, and provide reliable results for product development. Durable and easy to use, with features and controls typically found on higher-end systems. Accessories to test as low as 5 N (1.1 lbf) on a range of specimens.

Applications

- Tension

- Compression

- Flex/Bend

- Shear

Test Specimens

- Ceramics

- Metals

-

Polymers

- Elastomeric Materials

- Elastomers

- Plastics

- Polymers

- Rubber

Test Standards

- ASTM A48-A48M

- ASTM D412

- ASTM D624

- ASTM D638

- ASTM D695

- ASTM D790

- ASTM D882

- ASTM E21

- ASTM E290

- ASTM E517

- ASTM E646

- ASTM E8-E8M

- ASTM E9

- ISO 10113

- ISO 10275

- ISO 6892-1

- ISO 6892-2

- ISO 7438

- ISO 178

- ISO 527-2

- ISO 527-3

- ISO 604

Key Product Features

Cost Efficient

Dual-test zone design uses single load cell for two types of tests

Easy, Intuitive Use

Self-ID capability for calibration and auto-ranging

Accurate

1000 Hz data acquisition rate provides more meaningful analysis

Durable

Heavy duty components support longer system life

Model Comparison

Model E42

- Maximum rated force capacity:

- E42.503: 5 kN (1100 lbf)

- Single test zone

- Tabletop

- Standard and extended height

Model E43

- Maximum rated force capacity:

- E43.104: 10 kN (2200 lbf)

- E43.504: 50 kN (11000 lbf)

- Single test zone

- Tabletop

- Standard and extended height

Model E44

- Maximum rated force capacity:

- E44.304: 30 kN (6600 lbf)

- Dual test zones

- Floor-standing

- Standard and extended height

Model E45

- Maximum rated force capacity:

- E45.105: 100 kN (22000 lbf)

- E45.305: 300 kN (66000 lbf)

- E45.605: 600 kN (132000 lbf)

- Dual test zones

- Floor-standing

- Standard height for 600 kN; standard and extended height for 100 kN and 300 kN

Full Product Information

MTS EXCEED SERIES 40 SPECIFICATIONS - COMPARATIVE

|

Model |

E42.503* |

E43.104 |

E43.504 |

|

|

Maximum rated force capacity |

5 kN (1100 lbf) |

10 kN (2200 lbf) |

50 kN (11000 lbf) |

|

|

|

|

|

|

|

|

Force capacity options |

5 N, 10 N, 20 N, 50 N, 100 N, 200 N, 500 N, 1 kN, 2 kN, 5 kN 1 lbf, 2 lbf, 5 lbf, 10 lbf, 20 lbf, 45 lbf, 110 lbf, 220 lbf, 450 lbf, 1100 lbf |

5 N, 10 N, 20 N, 50 N, 100 N, 200 N, 500 N, 1 kN, 2 kN, 5 kN, 10 kN 1 lbf, 2 lbf, 5 lbf, 10 lbf, 20 lbf, 45 lbf, 110 lbf, 220 lbf, 450 lbf, 1100 lbf, 2200 lbf |

20 kN, 30 kN, 50 kN

4500 lbf, 6700 lbf, 11000 lbf |

|

|

Frame type |

Tabletop |

Tabletop |

Tabletop |

|

|

Test zones (single/dual) |

Single |

Single |

Single |

|

|

Maximum test speed |

508 mm/min (20 in/min) |

508 mm/min (20 in/min) |

508 mm/min (20 in/min) |

|

|

Minimum test speed |

0.001 mm/min (0.00004 in/min) |

0.001 mm/min (0.00004 in/min) |

0.001 mm/min (0.00004 in/min) |

|

|

Position resolution |

0.000051 mm (0.0000022 in) |

0.000041 mm (0.0000016 in) |

0.00006 mm (0.0000023 in) |

|

|

Vertical test space crosshead travel |

Standard Extended |

700 mm (27.6 in) 1000 mm (39.4 in) |

1000 mm (39.4 in) 1300 mm (51.2 in) |

1000 mm (39.4 in) 1300 mm (51.2 in) |

|

Space between columns |

100 mm (3.94 in)* |

340 mm (13.4 in) |

420 mm (16.5 in) |

|

|

Frame height |

Standard Extended |

1300 mm (51.18 in) 1600 mm (63.0 in) |

1617 mm (63.7 in) 1917 mm (75.5 in) |

1770 mm (69.7 in) 2070 mm (81.5 in) |

|

Frame width |

642 mm (25.28 in) |

681 mm (26.81 in) |

820 mm (32.3 in) |

|

|

Frame depth |

582 mm (22.91 in) |

588 mm (23.15 in) |

775 mm (30.5 in) |

|

|

Weight |

Standard Extended |

120 kg (265 lb) 130 kg (287 lb) |

120 kg (265 lb) 130 kg (287 lb) |

325 kg (716 lb) 345 kg (761 lb) |

|

Power requirement |

Single-phase 200-240 V AC, 3 Amp 50/60 Hz, 600 W |

Single-phase 200-240 V AC, 3 Amp 50/60 Hz, 600 W |

Single-phase 200-240 V AC, 6 Amp 50/60 Hz, 1600 W |

|

* For single-column load frame this measurement denotes the distance from the center of the clevis to the front of the column cover.

|

Model |

E44.304 |

E45.105 |

E45.305 |

E45.605 |

|

Maximum rated force capacity |

30 kN (6600 lbf) |

100 kN (22000 lbf) |

300 kN (66000 lbf) |

600 kN (132000 lbf) |

|

Force capacity options |

100 N, 250 N, 500 N, 1 kN, 2 kN, 5 kN, 10 kN, 20 kN, 30 kN 20 lbf, 50 lbf, 110 lbf, 220 lbf, 450 lbf, 1100 lbf, 2200 lbf, 4400 lbf, 6600 lbf |

50 kN, 100 kN

11000 lbf, 22000 lbf |

200 kN, 300 kN

44000 lbf, 66000 lbf |

600 kN

132000 lbf |

|

Frame type |

Floor-standing |

Floor-standing |

Floor-standing |

Floor-standing |

|

Test zones (dual) |

Dual |

Dual |

Dual |

Dual |

|

Maximum test speed |

508 mm/min (20 in/min) |

508 mm/min (20 in/min) |

250 mm/min (9.84 in/min) |

254 mm/min (10 in/min) |

|

Minimum test speed |

0.001 mm/min (0.00004 in/min) |

0.001 mm/min (0.00004 in/min) |

0.001 mm/min (0.00004 in/min) |

0.001 mm/min (0.00004 in/min) |

|

Position resolution |

0.000040 mm (0.0000015 in) |

0.000041 mm (0.0000016 in) |

0.000017 mm (0.0000007 in) |

0.000016 mm (0.0000006 in) |

|

Vertical test space crosshead travel Standard Extended |

1150 mm (45.28 in) 1450 mm (57.09 in) |

1050 mm (41.34 in) 1350 mm (53.15 in) |

1100 mm (43.30 in) 1400 mm (55.12 in) |

1300 mm (51.2 in) |

|

Space between columns |

400 mm (15.75 in) |

600 mm (23.62 in) |

580 mm (22.83 in) |

750 mm (29.52 in) |

|

Frame Height Standard Extended |

1862 mm (73.3 in) 2162 mm (85.12 in) |

2133 mm (83.98 in) 2433 mm (95.79 in) |

2360 mm (92.91 in) 2660 mm (104.72 in) |

2820 mm (111.02 in) |

|

Frame width |

845 mm (33.27 in) |

1230 mm (48.43 in) |

1215 mm (47.83 in) |

1660 mm (65.35 in) |

|

Frame depth |

716 mm (27.19 in) |

870 mm (34.25 in) |

960 mm (37.80 in) |

1272 mm (50.08 in) |

|

Weight Standard Extended |

435 kg (959 lb) 450 kg (992 lb) |

1400 kg (3086 lb) 1450 kg (3197 lb) |

1700 kg (3748 lb) 1750 kg (3758 lb) |

3500 kg (7716 lb) |

|

Power requirement |

Single-phase 200-240 V AC, 6 Amp 50/60 Hz, 1200 W |

Single-phase 200-240 V AC, 10 Amp 50/60 Hz, 2000 W |

Three-phase 380-415 V AC, or 440-480 V AC, 6.8 Amp 50/60 Hz, 5000 W |

Three-phase 380-415 V AC, or 440-480 V AC, 10 Amp 50/60 Hz, 5000 W |

MTS EXCEED SERIES 40 SPECIFICATIONS - COMMON

ISO 7500 Class 0.5 / Class 1 or ASTM E4

|

Low Profile Force Accuracy* (bending beam & shear beam) |

± 0.5% of applied force |

± 1.0% of applied force |

|

Low Profile Force Range** (bending beam & shear beam) |

1 to 100% of rated force capacity |

0.5 to 1% of force rated capacity |

|

S-Beam Force Accuracy* |

± 1.0% of applied force |

|

|

S-Beam Force Range** |

1 to 100% of rated force capacity |

|

|

Rated maximum force at max. test speed |

100% |

|

|

Rated maximum test speed at maximum force |

100% |

|

|

Speed accuracy |

Set speed < 0.01 mm/min: speed accuracy is within ± 1.0% of set speed Set speed ≥ 0.01 mm/min: speed accuracy is within ± 0.5% of set speed |

|

|

Position accuracy |

Within ± 0.5% |

|

|

Strain accuracy*** (depending on extensometer) |

± 0.5% of applied strain |

|

|

Security protection |

Over-force, travel limits, over-voltage and others |

|

|

Over force protection |

10% |

|

|

Data acquisition rate |

Up to 2500 Hz |

|

|

Control loop rate |

5000 Hz |

|

|

Environmental requirements (For indoor use only) |

|

|

|

Operating temperature |

5° C to 40° C (41° F to 104° F) |

|

|

Operating humidity |

5% - 85% non-condensing |

|

|

Storage temperature |

-18° C to 49° C (0° to 120° F) |

|

|

Maximum storage humidity |

90% non-condensing |

|

|

Maximum altitude |

2000 meters |

|

|

Motor & drive system |

AC Servo Motor |

|

|

Ballscrews |

Pre-loaded |

|

|

Position measurement |

Encoder |

|

|

User Digital Inputs/Outputs (DIO) |

4 user Digital Inputs and 4 user Digital Outputs |

|

|

Encoder capacity |

4 Encoders |

|

* Applicable onsite calibration services are available to meet ISO 7500-1, ASTM E4.

** Range dependent upon controller settings and operating environment.

*** Extensometer calibration services are available to meet ISO 9513, ASTM E83.

|

Electromechanical Attachment Specifications |

|

|

|

|

|

|||

|

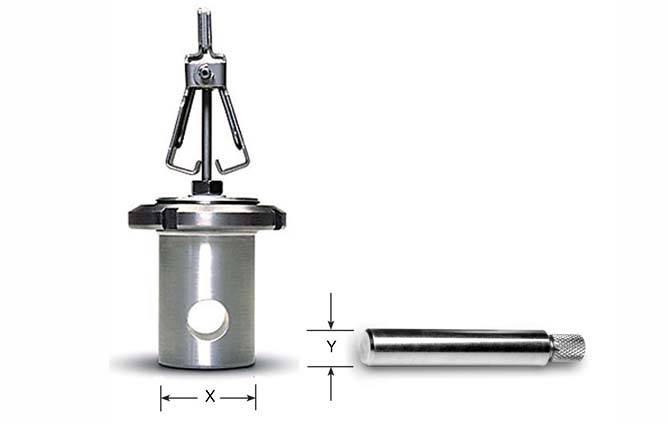

Clevis Pin Connection |

Type B |

Type C (AL) |

Type C (STL) |

Type D |

Type E |

Type F |

Type 20 |

Type 40 |

|

Max. Load Capacity |

10 N |

200 N |

2.5 kN |

150 kN |

300 kN |

600 kN |

30 kN |

100 kN |

|

Clevis Diameter (X) |

12.7 mm (0.50 in) |

15.9 mm (0.625 in) |

15.9 mm (0.625 in) |

31.7 mm (1.25 in) |

60 mm (2.36 in) |

90 mm (3.54 in) |

20 mm (0.787 in) |

40 mm (1.57 in) |

|

Pin Diameter (Y) |

4.7 mm (0.186 in) |

6.4 mm (0.25 in) |

6.4 mm (0.25 in) |

12.7 mm (0.50 in) |

28 mm (1.1 in) |

40 mm (1.57 in) |

10 mm (0.039 in) |

18 mm (0.71 in) |

Service and Support

Our experts are here to help keep you up and running.

Related Products, Parts or Accessories

TestSuite Software

Long Travel Extensometer (LTX850)

S-Beam Load Cells For Exceed Systems

Looking for more products?

Go to Solution FinderCONTACT US TODAY

Ready for a quote or need more information? We're here to help. Request A QuoteResources

TestSuite TW Flexibility

Meet unique materials testing requirements with modifiabl…

Versatile Monotonic Test Systems

MTS systems integration engineer describes monotonic test sy…

New Optical Extensometer

Simplified non-contacting axial strain measurement & con…

Tensile Testing 101

An MTS application engineer demonstrates a simple tensile te…

More Than Double Data Rate

New MTS Exceed system controller offers greater insight into…

Bend Testing 101

An MTS application engineer demonstrates a 3-point bend test…

Increasing Production of PPE & Medical Consumables

See testing solutions that help accelerate production of cri…

MTS TestSuite TW Software

Efficient and versatile software for productive materials an…

Tensile Testing of Structural Plastics

MTS application engineers discuss common solutions for tensi…

6 Tips for Accurate Compression Testing

MTS staff scientist outlines best practices for compression …

Choose the Best Grip for Plastics & Rubber Testing

Quick review of various tensile testing grip types and their…