MTS responds to evolving test requirements for electric vehicles, commercial trucks, and off-highway vehicles with a selection of 6DOF MAST systems capable of testing larger, heavier specimens at higher frequencies.

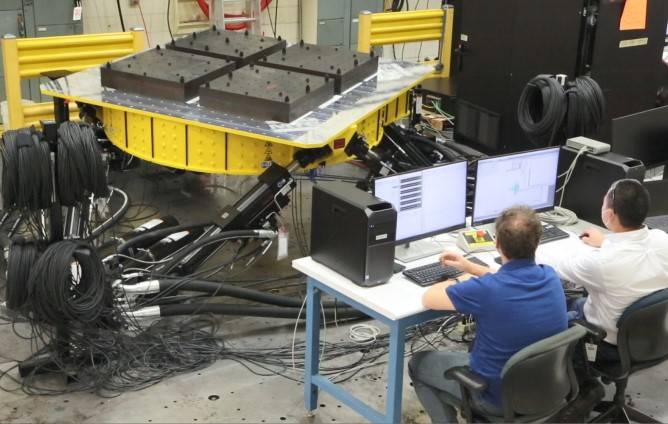

The MTS Multi-Axial Simulation Table (MAST) portfolio features a selection of high-payload systems capable of subjecting heavy (up to 3000 kg), large-geometry test articles to real-world vibration phenomena in six-degree-of-freedom (6DOF) at frequencies up to 200 Hz. This level of performance is required to test heavy electric vehicle batteries and battery packs, and large components, assemblies, and subsystems used in commercial trucks and off-highway agricultural, construction, mining, and forestry vehicles.

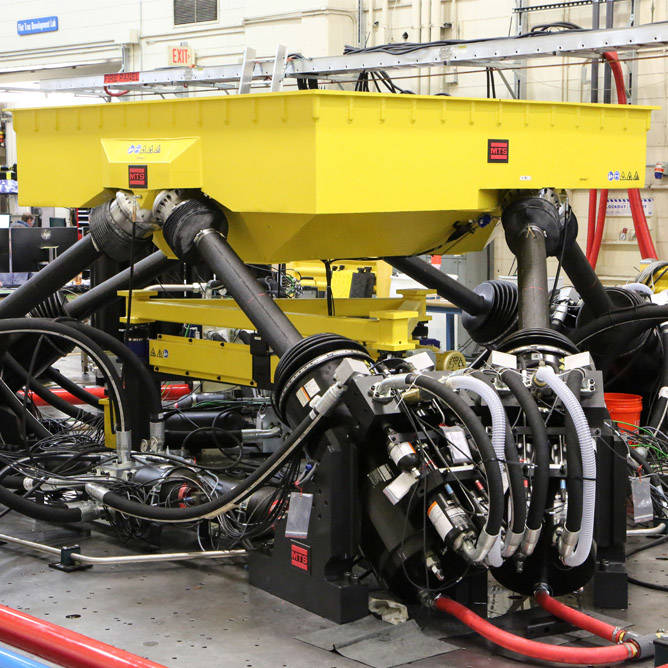

High-Payload MAST systems integrate highly stiff simulation tables, productivity-enhancing application software, advanced 6DOF hexapod controls, and an array of state-of-the-art MTS hydromechanical technologies.

| Model 353.50 |

| Maximum Payload |

3000 kg |

| Simulation Frequency* |

up to 200 Hz |

| Table size |

2.5 x 2.5 m |

Linear Acceleration*

|

|

Vertical (Z)

|

9.5 g |

|

Lateral (Y)

|

5.5 g |

|

Longitudinal (X)

|

6.0 g |

| * maximum payload |

| Model 354.20 |

| Maximum Payload |

2000 kg |

| Simulation Frequency* |

up to 200 Hz |

| Table size |

2.5 x 2.5 m |

Linear Acceleration*

|

|

Vertical (Z)

|

6.0 g |

|

Lateral (Y)

|

4.2 g |

|

Longitudinal (X)

|

4.8 g |

| * maximum payload |

RPC Connect application software optimizes durability test efficiency and productivity, while sophisticated FlexTest (793) compensation tools maximize test system controllability and fidelity to accelerate RPC drive file convergence.

State-of-the-art MTS hydraulic distribution, accumulation, and actuation technologies safely and efficiently deliver all the energy needed for accurate and repeatable vibration testing of very large, heavy ground vehicle specimens.