Subjecting full-scale structures to real-world loading poses enormous challenges for civil engineering test labs. Working with MTS, the University of Minnesota built and maintains one of the world's highest capacity seismic test systems, capable of applying massive forces to very large specimens in six degrees of freedom.

Professor Catherine French, PhD, PE - Laboratory Director explores the unique capabilities of the University of Minnesota Multi-Axial Subassemblage Test (MAST) Lab, used by researchers worldwide for applying realistic loads to large-scale specimens, such as core walls, beam-column frame systems, wind turbine tower bases, and more. Results from these test are used to verify design codes, analyze new materials and systems, and optimize civil project safety and cost-effectiveness.

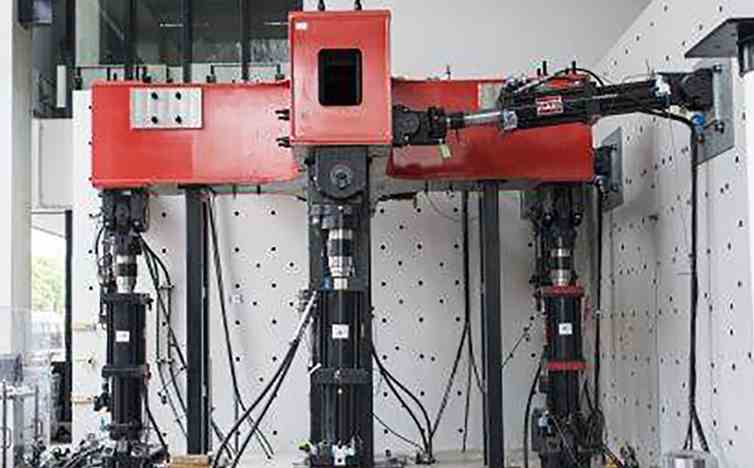

One of ten original NEES (Network for Earthquake Engineering Simulation) sites, the University of Minnesota MAST Lab integrates state-of-the-art MTS testing technologies, including 6 Degree-of-Freedom (6DOF) Control, ultra-low friction hydrostatic bearings, and advanced quasi-static and real-time hybrid simulation

- Capable of testing full-scale civil structures and components up to 8.7m tall and 6m x 6m in plan

- Highly stiff steel cruciform crosshead design

- MTS Linear Hydraulic Actuators: 4 Vertical, 2 Longitudinal, 2 Lateral

- Vertical Force Capacity: 5.8MN

- Vertical Displacement: +/- 500mm

- Horizontal Force Capacity: 3.9MN (longitudinal & lateral)

- Horizontal Displacement:

+/- 400mm