Quieter electric vehicles and comfort-focused autonomous vehicles are driving tougher new suspension NVH requirements - and the evolution of MTS damper testing technology.

The innovative Model 853 draws on MTS' deep expertise in both damper and elastomer testing to achieve the performance needed to study the complete spectrum of damper noise phenomena, including structure-borne chuckle.

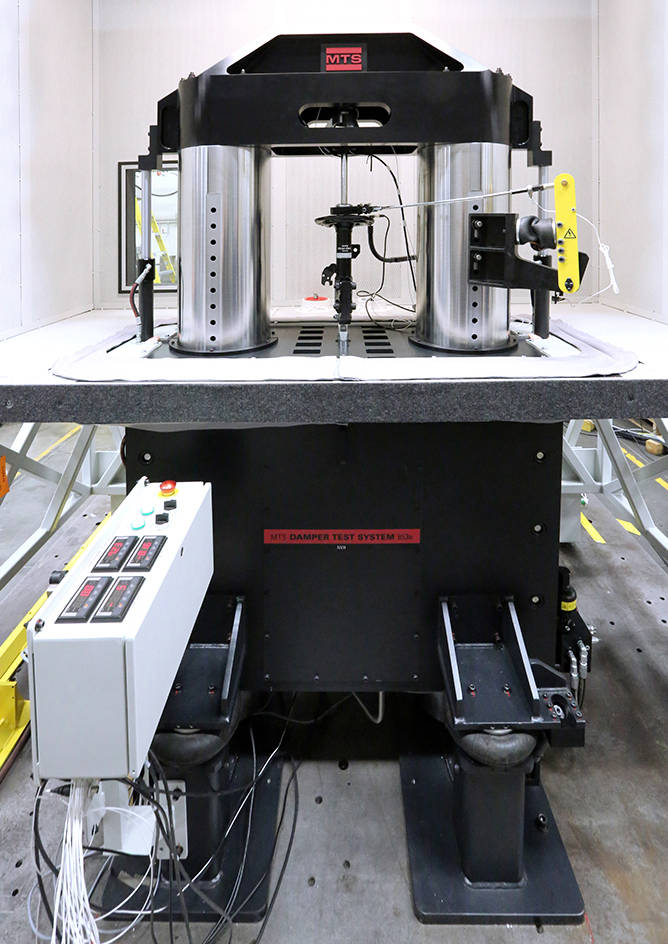

High-bandwidth transducers and accelerometers - typically used in elastomer testing - perform damper NVH measurements with fidelity and accuracy up to 800 Hz. A highly stiff elastomer system load frame with larger diameter columns, a thicker crosshead, and more robust base prevents the resonant modes that can corrupt test data. Linear electric actuation technology provides the clean sinusoidal input and low total harmonic distortion (THD) required for meaningful chuckle testing.

The inherent low audible noise of the Model 853 system combined with the available integrated acoustic chamber enables air-borne "swish" testing with background noise less than 40 decibels.

The multi-functional Model 853 can also perform elastomer testing with an optional elastomer test fixture, MTS Elastomer Testing software, and a versatile FlexTest controller capable of reproducing any signal.