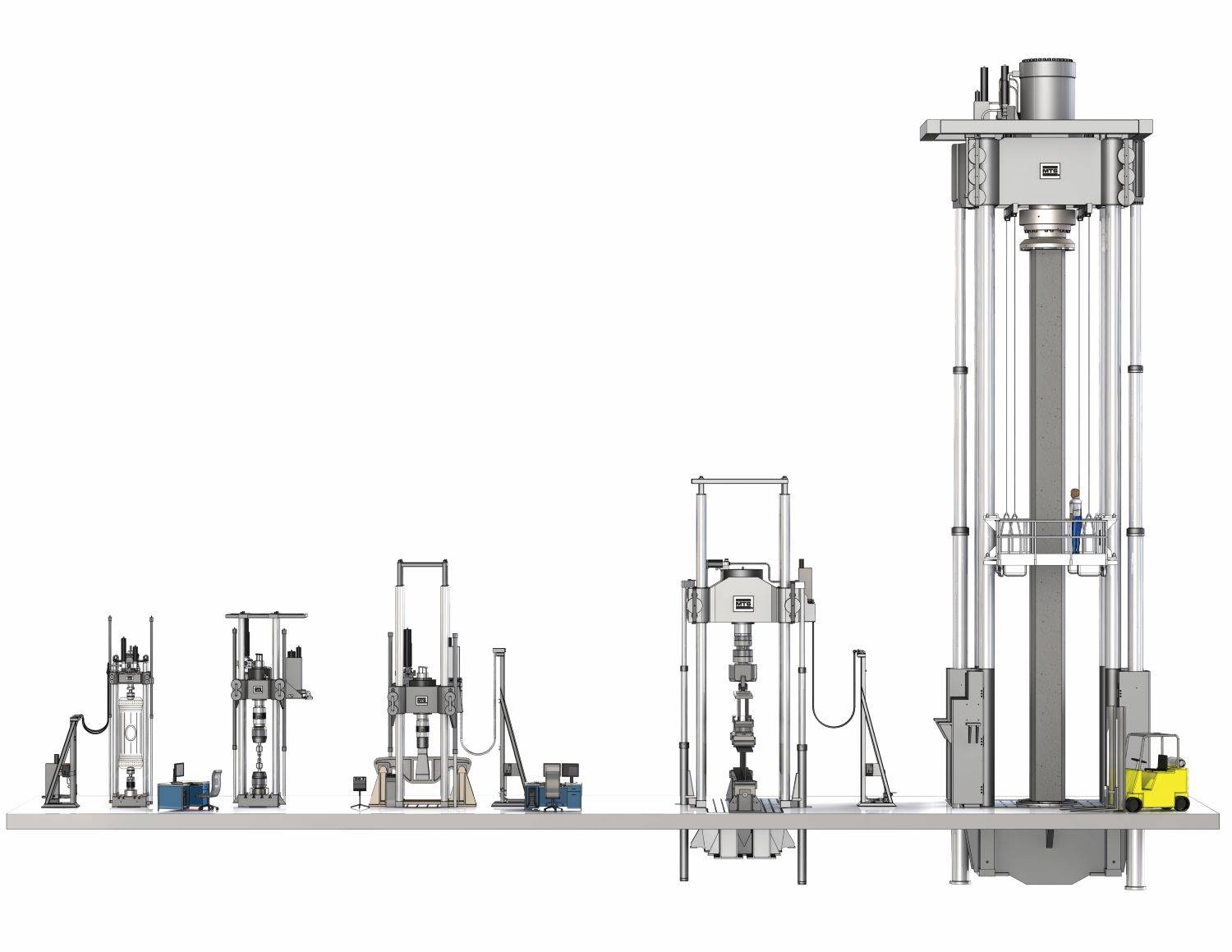

Series 311 High-Force Test Systems

Ultra-stiff, four-column servohydraulic load frames, dynamically rated to deliver loads ranging from 1 to 30 MN. Higher capacity load frames and unique features can be custom engineered to order.

Applications

- Bend

- Compression

- Dynamic Testing

- Fatigue

- Fatigue and Fracture

- Tension

- Stiffness and Strength Measurement

Test Specimens

- Concrete

- Materials

- Aircraft Panels

- Wind Turbine Blade Sub-components

- Building Materials

- Metals

- Piping and Tubing

- Rebar

- Chain

- Structural Steel

- Wire and Cable

Key Product Features

Industry Standard

A proven leader in developing servohydraulic technology

Versatile

Dozens of available accessories including bending fixtures, compression platens and high force grips are available to provide a wide range of testing capabilities

Accurate/Repeatable Results

Superior frame stiffness and alignment produces accurate results

High Performance

Systems can be engineered with higher performance packages to meet any testing requirement

Model Comparison

311.31 / 311.32

- Max force capacity: 1.0 MN / 1.2MN (265 kip)

- Column Diameter: 4 inches

- Load Frame Height: Approx. 5.5m (8 ft)

- Load Frame Weight: Approx. 4100 kg (9100 lb)

- Customized models and performance packages available

311.41

- Max force capacity: 2.5MN (550 kip)

- Column Diameter: 6 inches

- Load Frame Height: Approx. 6.7m (22 ft)

- Load Frame Weight: Approx. 9525 kg (21,000 lb)

- Customized models and performance packages available

311.51

- Max force capacity: 5MN (1100 kip)

- Column Diameter: 8 inches

- Load Frame Height: Approx. 8.5m (28 ft)

- Load Frame Weight: Approx. 21,500 kg (47,500 lb)

- Customized models and performance packages available

311.71

- Max force capacity: 10MN (2200 kip)

- Column Diameter: 10 inches

- Load Frame Height: Approx. 11m (36 ft)

- Load Frame Weight: Approx. 55,000 kg (120,000 lb)

- Customized models and performance packages available

311.91

- Max force capacity: 30MN (6600 kip)

- Column Diameter: 17 inches (425mm)

- Load Frame Height: Approx. 20m ( 65ft)

- Load Frame Weight: Approx. 275,000 kg (600,000lb)

- Customized models and performance packages available

Full Product Information

|

1. |

Optional Tie Bar |

|

2. |

High-Accuracy Linear Variable Differential Transducer (LVDT) |

|

3. |

Precision-machined, ultra-stiff columns |

|

4. |

Optional Hydraulic Crosshead Positioning Cylinders |

|

5. |

High-Stiffness Crosshead - Integrated Actuator - Integrated Hydraulic Manifold - Close-coupled Accumulators |

|

6. |

Optional Hose Stand |

|

7. |

Hydraulic Service Manifold (HSM) - Optional hose stand-mounted - Optional crosshead-mounted (shown) - Optional floor-standing |

|

8. |

Crosshead Lift/Lock Controls - Optional hose stand-mounted (shown) - Optional floor-standing |

|

9. |

Optional Hydraulic Grip Supply |

|

10. |

Load Frame Base Options - Standard T-Slot (shown) - Integrated Strong Floor |

|

11. |

Precision Force Transducer - Base-mounted (shown) - Actuator-mounted |

|

12. |

Optional High-Force Accessories - Compression Platens - Hydraulic Wedge Grips (shown) - Bend Fixtures - Custom Fixtures |

|

13. |

Crosshead Clamping Mechanism |

|

14. |

High-Performance MTS Actuator - Crosshead-mounted - High-Stiffness - Doubled-ended - Dynamically rated |

|

|

|

Standard Models |

Custom Models |

||||||

|

Load Frame Specifications |

Units |

311.31 |

311.32 |

311.41 |

311.51 |

311.61 |

311.71 |

311.81 |

311.91 |

|

Dynamic Force Ratings |

kN |

1000 |

1200 |

2500 |

5000 |

7500 |

10,000 |

20,000 |

30,000 |

|

(kip) |

(220) |

(265) |

(550) |

(1100) |

(1650) |

(2200) |

(4400) |

(6600) |

|

|

Standard Dynamic Strokes |

mm |

150, 250 |

150, 250 |

150, 300 |

300 |

Custom load frame dimensions vary according to customers' specific application requirements. Consult an MTS Applications Engineer for more information. |

|||

|

(in) |

(6, 10) |

(6, 10) |

(6,12) |

(12) |

|||||

|

Column Diameter |

mm |

101.6 |

101.6 |

152.4 |

203.2 |

||||

|

(in) |

(4.00) |

(4.00) |

(6.00) |

(8.00) |

|||||

|

Column Spacing (width) |

mm |

711.2 |

711.2 |

762 |

1016.0 |

||||

|

(in) |

(28.0) |

(28.0) |

(30.0) |

(40.0) |

|||||

|

Column Spacing (depth) |

mm |

406.4 |

406.4 |

508.0 |

812.8 |

||||

|

(in) |

(16.0) |

(16.0) |

(20.0) |

(32.0) |

|||||

|

Load Frame Height |

mm |

2946-5486 |

2946-5486 |

Note3 |

4470-8534 |

||||

|

(min-max) |

(in) |

(116-216) |

(116-216) |

Note3 |

(176-336) |

||||

|

Specimen and Grip Spacing |

mm |

254-2794 |

254-2794 |

Note2 |

450-4500 |

||||

|

(min-max) |

(in) |

(10-110) |

(10-110) |

Note2 |

(17.8-177) |

||||

|

Base Width (width) |

mm |

914.4 |

914.4 |

1066.8 |

1422.4 |

||||

|

(in) |

(36.0) |

(36.0) |

(42.0) |

(56.0) |

|||||

|

Base Width (including lifts) |

mm |

1219 |

1219 |

1492.5 |

1903 |

||||

|

(in) |

(48.0) |

(48.0) |

(58.8) |

(75.0) |

|||||

|

Base Depth |

mm |

1016 |

1016 |

1168.4 |

1397 |

||||

|

(in) |

(40.0) |

(40.0) |

(46.0) |

(55.0) |

|||||

|

Base Height (from floor) |

mm |

280.9 |

280.9 |

332 |

450 |

||||

|

(in) |

(11.06) |

(11.06) |

(13.06) |

(17.8) |

|||||

|

Hose Stand Spacing (max) |

mm |

921 |

921 |

2479 |

2479 |

||||

|

(in) |

(36.3) |

(36.3) |

(97.7) |

(97.7) |

|||||

|

Hose Stand Width |

mm |

991 |

991 |

991 |

991 |

||||

|

(in) |

(39.0) |

(39.0) |

(39.0) |

(39.0) |

|||||

|

Hose Stand Depth |

mm |

688 |

688 |

688 |

688 |

||||

|

(in) |

(27.1) |

(27.1) |

(27.1) |

(27.1) |

|||||

|

Hose Stand Height |

mm |

2426 |

2426 |

2819 |

3200 |

||||

|

(in) |

(95.5) |

(95.5) |

(111.0) |

(126.0) |

|||||

|

Approximate Crosshead Weight |

kg |

1225 |

1225 |

2903 |

7938 |

||||

|

(lb) |

(2700) |

(2700) |

(6400) |

(17,500) |

|||||

|

Approximate Total Weight |

kg |

4100 |

4100 |

9525 |

21500 |

||||

|

(lb) |

(9100) |

(9100) |

(21,000) |

(47,500) |

|||||

|

System Stiffness4 |

N/m |

1.6 X 109 |

1.6 X 109 |

3.1 X 109 |

3.9 X 109 |

||||

|

lbf/in |

9.3 X 106 |

9.3 X 106 |

17.4 X 106 |

22.6 X 106 |

|||||

|

1.Model 311.31 & 311.32 with actuator retracted, 311.41 & 311.51 with actuator at mid-stroke |

|

2.Model 311.41 150 mm stroke is 400 – 3000 mm (15.75 – 118.1 in), 311.41 300 mm stroke is 400 – 3385 (13.31 – 133.3 in) |

|

3.Model 311.41 150 mm stroke is 3554 – 6154 (140.0 – 242.3 in), 311.41 300 mm stroke is 3720 – 6768 (146.5 – 266.5 in) |

|

4.Stiffness calculated at a crosshead height of 2 meters (78.7 inch) above the base. |

Service and Support

Our experts are here to help keep you up and running.

Related Products, Parts or Accessories

Landmark® Servohydraulic Test Systems

TestSuite Software

SilentFlo™ 515 & 525 Hydraulic Power Units (HPU)

Looking for more products?

Go to Solution FinderCONTACT US TODAY

Ready for a quote or need more information? We're here to help. Request A QuoteResources

High-Force Testing Challenges

MTS application engineers discuss the nuances and challenges…

Using C3 Performance to Accelerate Complex Structural Tests

Use Cases; NIAR & NRC- Canada

Ultra-high-strength Rebar Testing

Meeting ultra-high-strength rebar testing requirements to Im…

Protecting Hydraulic System Health

Discover the advantages of the MTS Fluid Care Program.

The Case for Calibration

MTS calibration can help increase data validity and lab effi…

8% More Energy Efficient

Reduce SilentFlo 505 HPU operating costs with a pump/motor m…