|

New demands for increased fuel efficiency, lower emissions and improved passenger comfort are changing how automobile manufacturers approach vehicle design, presenting an array of challenges for the industry at large and mechanical testing specifically. For the past decade, Byron Saari, Principal R&D Engineer at MTS Systems, has been focusing on the testing challenges. “It started with some really interesting inquiries from leading-edge damper, or shock absorber, suppliers about 10 years ago,” Saari said. “They asked about an NVH system that would be suitable for testing a structure-borne noise phenomenon called “chuckle.” It turned out to be a tall order.” |

|

|

Byron Saari is integrating elastomer testing technology (foreground) and linear electro-magnetic actuation (background) to develop an effective means for studying structure-borne chuckle. |

|

|

What Saari was witnessing was the emergence of market forces that would soon complicate noise, vibration, and harshness (NVH) testing for dampers. The rise of autonomous vehicles, for example, is putting greater emphasis on ride and comfort. Lighter vehicles and quieter powertrains have improved fuel efficiency and reduced emissions but have also made it more difficult to control noise generated by (and transmitted by) the shock absorbers. In fact, now that powertrain, drivetrain, and aerodynamic noise have all been thoroughly reduced, residual damper noise is more prominent. While airborne “swish” is comparatively easy to identify and mitigate at the component level, structure-borne chuckle noise presents a more troubling issue. Chuckle (also called “clatter,” “rumble,” and “trunk of lumber”) has yet to be fully understood. It originates as a mechanical vibration in the body of the shock absorber. Impedance coupling in the upper mount turns the mechanical vibration into acoustic noise in the cab. As such, chuckle is model- or platform-dependent and cannot be easily identified or resolved at the component level. Serious chuckle problems are often discovered during the prototype phase and can be extremely disruptive to the vehicle development budget and schedule. Chuckle presents unique challenges for mechanical testing as well. Unlike swish analysis, chuckle testing has no standardized equipment or procedures. The phenomenon is difficult to replicate in the test lab because it is not always clear what noise signature will cause an issue. “Even if you can isolate a frequency that causes chuckle for a particular shock absorber, you may not be able to replicate it in a different test bench due to existing test system resonances,” Saari said. “All of these issues make it very difficult for damper suppliers to meet OEM specifications for damper noise in the cab. As a result, NVH testing has become a much more critical part of the development process.” Conventional damper test equipment is not well suited for characterizing chuckle. The mechanical vibration needs to be measured with an accelerometer at the top of the damper rod, which is difficult to do at high frequencies without the test rig influencing the results. In addition, damper test systems are typically used to run tests with a maximum input (sinusoidal or road data) of 25 Hz. If higher frequencies are unintentionally excited in the test system, it is generally not a concern. Unfortunately, chuckle happens at frequencies from 200 Hz to 500 Hz. If a 25 Hz sinusoid excites a 250 Hz harmonic, for example, it will be measured in the output of the piston rod. Analyzing this data would lead developers to conclude that the damper design has a 250 Hz chuckle problem, when in fact this is an effect of the harmonic distortion of the test system’s excitation. “To be truly effective at analyzing chuckle, a damper NVH solution needs to provide very pure sinusoidal excitation with very little total harmonic distortion, or THD,” Saari said. As it turns out, Saari is uniquely positioned to develop such a solution due to his many years at MTS spent researching and developing servohydraulic test systems for both damper and elastomer test applications. His work with customers worldwide helped shape both portfolios of products for the company, and he acquired deep domain expertise in the nuances of these complex tests. With insight from both domains, Saari envisioned a new test system design for studying damper NVH, one that would combine the capabilities of an elastomer test system with those of a damper test system. In 2014, MTS acquired Roehrig Engineering, Inc., developer of all-electric EMA damper test systems - renowned for high frequency response and programmability. The addition of linear Electro-Magnetic Actuation (EMA) technology provided the spark to set the new damper NVH solution in motion. The realization of Saari‘s damper NVH vision, then, would represent a fusion of conventional MTS elastomer with damper technologies and electro-magnetic actuation. |

|

|

The Model 853 NVH Damper System draws from servohydraulic damper (left), linear electro-magnetic damper (middle) and servohydraulic elastomer (right) test technologies. |

|

|

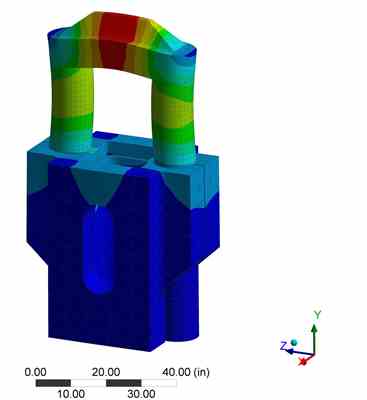

To perform damper NVH measurements with fidelity and accuracy up to the required 700 Hz, the system would employ high-bandwidth transducers that are typically used to measure displacement, force, and vibration in high-frequency elastomer test systems. It would also need an elastomer test system’s high-stiffness load frame, along with larger diameter columns, a thicker crosshead, and a more robust base to avoid the resonant modes that can corrupt measurements. |

|

|

The first modal frequency affecting data measurements of interest is above 700 Hz. |

|

|

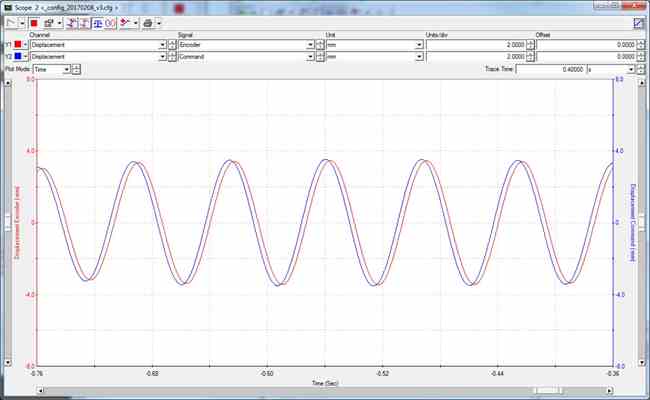

Linear EMA technology is an ideal source for the clean sinusoidal input and low harmonic distortion the system would require for effective chuckle testing. MTS’ EMA technology combines fixed, high-force neodymium magnets and moving air-core (ironless) electric motors. The lack of ferrous metal makes the motor extremely lightweight, which is what enables the actuator’s high frequency response and high acceleration. The ironless motor also means there is no attractive force between the motor and the magnet and therefore no risk of cogging effects that can compromise the velocity waveform. |

|

|

Command (blue) vs. Response (red), indicating low Total Harmonic Distortion (THD) for a 15 Hz excitation. |

|

|

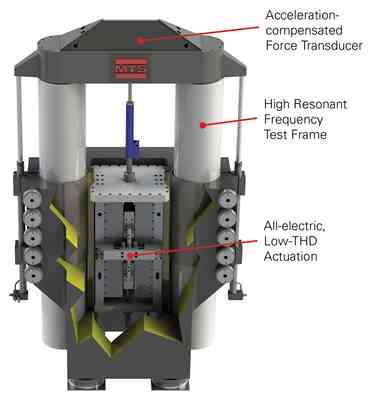

The result of this fusion is the Model 853 NVH Damper System – purpose-built for NVH testing of dampers and shock absorbers. Specification-wise, the system will perform measurements with fidelity and accuracy up to 700 Hz. It will be rated at 15 to 20 kN, deliver 3 m/s simultaneous dynamic force and velocity and 1 kN static force standard with optional increased capacity. Versatile FlexTest® controller technology will make the system capable of reproducing virtually any type of signal (sine block, sweeps, road signals). In addition, high bandwidth PIDF (Proportional Integral Derivative Feedforward) control will enable it to follow a specified wave shape precisely without iterations. |

|

|

The Model 853 NVH Damper System – purpose-built for NVH testing of dampers and shock absorbers. |

|

|

Saari believes the Model 853 will help test labs perform chuckle testing more easily, address the entire range of standard damper noise phenomena, including swish and squeak, perform basic damper characterization, and even provide elastomer testing functionality. “This new system will be an important advance in the field of NVH testing,” Saari said. “It fills a critical gap in damper test labs and gives test teams the standardized equipment necessary to address a persistent issue in the development cycle.” |

|

Adapting to Evolving Damper NVH Requirements

Learn how state-of-the-art MTS damper test solutions can benefit your new vehicle development.

Contact your MTS RepresentativeResources

Model 853 Damper NVH System

Analyze the complete spectrum of damper noise and vibration …

Next-Generation EMA Damper Performance Test Systems

Optimized EMA line to launch in early 2025.

Factors to Weigh When Considering Electric or Hydraulic Test Systems

Guidance on damper test systems and road simulators

Testing High-performance Bike Suspensions

Tour the testing lab at Fox Factory, Inc. to see how they co…

Accelerate Active & Semi-active System Development

Explore the the advantages of proven mHIL technology.

Nissan Motor Co., Ltd.

Using hybrid simulation to evaluate damper system impacts on…

Introducing FlexTest Elite Performance Controllers

Increase channel count, system rate and computational cap…

The Road to RPC Connect

Cody Johnson explores RPC software - past, present and futur…

RPC Connect Software Preview: Webinar 1

Safa Mogharebi explores the new Graphical User Interface

RPC Connect Software Preview: Webinar 2

Safa Mogharebi explores the new Setup & Analyze Stages

RPC Connect Software Preview: Webinar 3

Safa Mogharebi explores the new Model & Simulate Stages

Test Rig Design

Build your own high-quality, reconfigurable component and su…

New Generation Flat-Trac Systems

MTS permanent magnet motors enhance torque capacity, resp…

Introducing an all-electric, durability capable Model 320 Tire-coupled Road Simulator

Featuring MTS Iron-core Linear Electric Actuation

Pushing Tire Testing into Uncharted Territory

NTRC equips world's most capable tire testing facility

Optimum Sample Rate for Servohydraulic Systems

Brad Thoen explores how system sample rate affects control f…

National Tire Research Center (NTRC): Transforming Tire Design

High-powered MTS tire test system enables manufacturers t…

The Promise of Virtual Testing

Using analysis tools to derive accurate loads, motion and da…

New Online Training Classes Available

Live, instructor-led introductory courses on our most common…

European Off-Highway Seminar

Explore the technologies and methods used to evaluate agricu…

Heavy Truck Durability Testing

Explore heavy truck testing technologies and methods.

Chassis NVH Testing

GNTP component and bushing NVH test stands.

Light Truck & Racing Tire Testing

Flat-Trac LTRe Force & Moment Measurement System

The Right 4-Poster: Servohydraulic or Electric?

Factors to weigh when comparing servohydraulic and electr…