French contract test laboratory acquires state-of-the-art MTS shake table to provide vibration and earthquake qualification capabilities to customers in the nuclear, automotive, rail, and naval sectors.

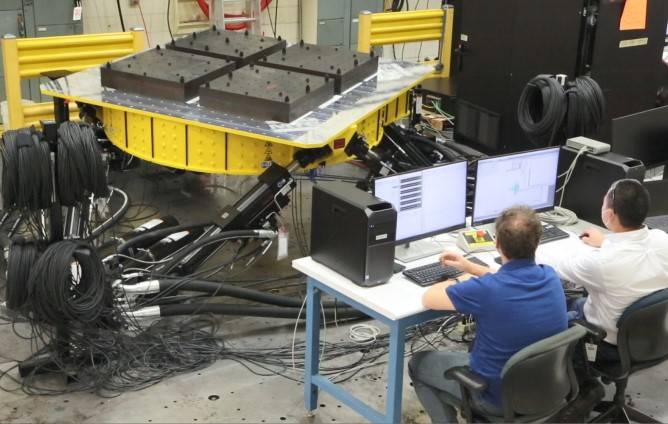

Sopemea, a subsidiary of the Apave Group, has added a Multi-Axial Simulation Table (MAST) to its vibration test laboratory in Vélizy, France. This heavy duty system can apply low-frequency forces and moments simultaneously on 3 axes (Fx,y,z; Mx,y,z) to specimens weighing up to 2 tons [2,000 kg]. This tri-axial loading enables far more precise replication of real world vibration phenomena than can be achieved with single-axis testing. Additionally, multi-axial testing requires substantially less preparation time as large, complex specimens need only be assembled and mounted to the table once.

The new MAST system was secured with funding from the Ministry of the Economy and Finance, awarded to Sopemea in 2021 as part of a recovery and support plan for France's nuclear power industry. It will be accesible to all manufacturers in the nuclear industry sector for meeting equipment qualification requirements.

Triaxial Table Inauguration - 9 March 2023: (left to right) Bernard Colomies, Technical Director of Sopemea & Project Pilot; Pascal Thevenot, Mayor of Vélizy; Bruno Gstach, Managing Director of Apave Développement & President of Sopemea; Catherine Michelin, General Manager of Sopemea.

A Model 354.20 MAST with a square 2.2 x 2.2 meter table enables Sopemea's customers to apply low frequency (<150 Hz) single, bi or tri-axis vibrations to equipment weighing up to 2,000 kg with accelerations up to 6 g and displacements of 200 mm.

A versatile FlexTest Controller, featuring a field-upgradable modular architecture, an advanced compensation toolkit, and industry-leading application software, provides Sopemea the agility to meet evolving requirements and expanding test missions.

EV Battery Vibration Test Application Requirements

Learn More