Seismic Simulators (Shake Tables)

The MTS seismic simulator portfolio features a host of standard, pre-engineered and custom tables for evaluating everything from nonstructural infrastructure to structural components and substructures to model-scale and full-scale civil structures. Precise seismic loading in up to six degrees-of-freedom can be applied to a broad array of test articles to evaluate their behavior under real-world earthquake conditions.

Applications

- Seismic Simulation

- Seismic Qualification

Test Specimens

- Civil Structures

- Substructures

- Components

Test Standards

- AC156 Earthquake Qualification Testing

Key Product Features

First-of-a-Kind

MTS has designed, installed and partnered with our customers on many of the world’s largest shake tables, including NIED, University of California - San Diego and Southwest Jiaotong University

Industry Standard

MTS has the largest world-wide installed base of seismic simulators. We have five decades of collaboration with the world’s premier civil engineering research institutions

Unmatched Expertise

PhD-level MTS System Integration Engineers provide expert guidance and training

Innovative Technology

Degree-of-Freedom Control, Real-time Control, Three-variable Control, Adaptive Control and Specimen Dynamics Compensation (SDC)

Model Comparison

1.5m Uni-axial Table

- Perform basic seismic research on scaled down structures

- Quick Installation and integration into existing labs

- Playback of scaled earthquake time history files

- Lower cost, entry-level option

3m Uni- & Bi-axial Tables

- Perform fundamental seismic research, up to 10 ton specimens can be tested

- Uniaxial and Biaxial variants available

- Can be pit mounted or come equipped with actuator buttresses

- Large displacement range (500 mm) to simulate realistic ground motions

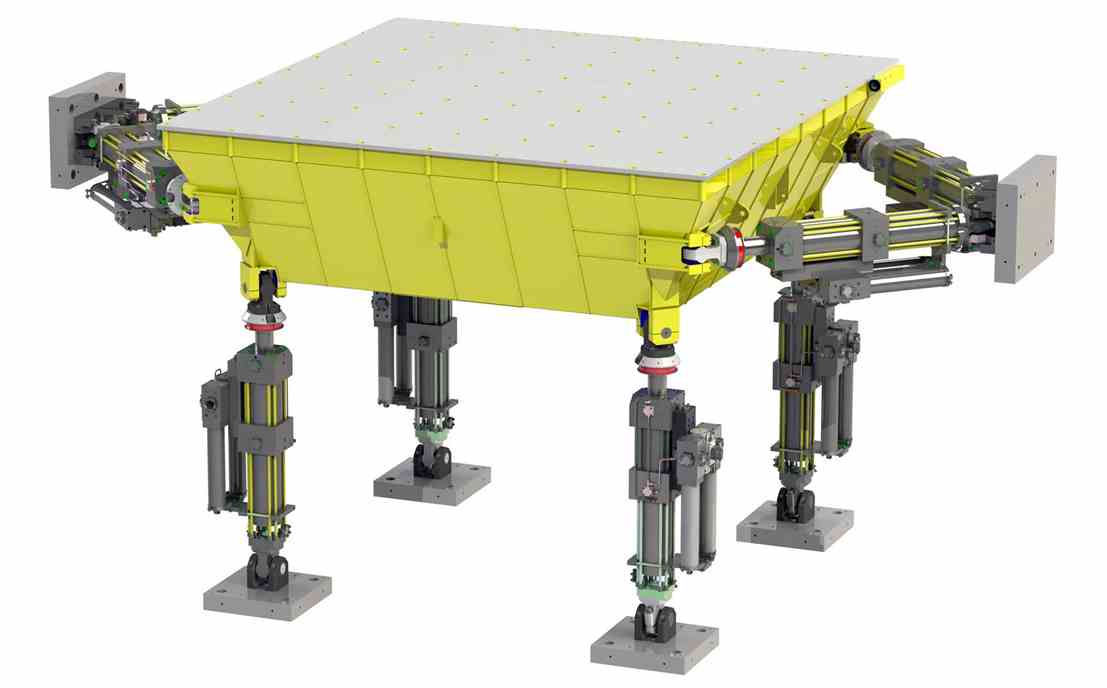

4m & 5m 6DOF Tables

- Perform full six degree of freedom seismic shaking

- Larger specimens (up to 40 ton payloads)

- Best suited for researchers looking for unique seismic performance

- Pre-engineered table offers faster lead time and lower cost when compared to custom designed tables.

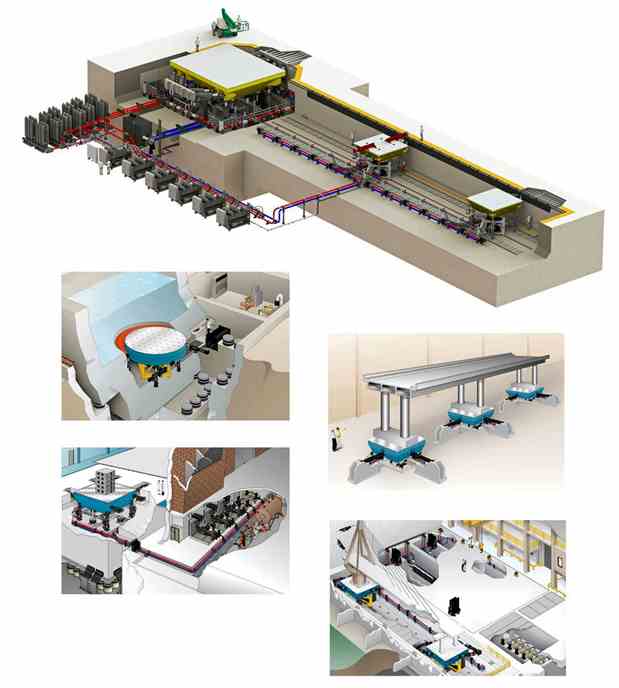

Custom Seismic Tables

- Perform complete/full-scale seismic research, MTS can design any size table and payload requirements per your specification

- 6 DOF or multiple tables working together

- MTS has the largest installed base of custom seismic simulators

2m x 2m Multi-Axial Simulation Table

-

Perform seismic qualification testing of components (AC156)

-

6 DOF using "hexapod" design

- Up to 2,000 kg payload

-

Up to 100 Hz control bandwidth

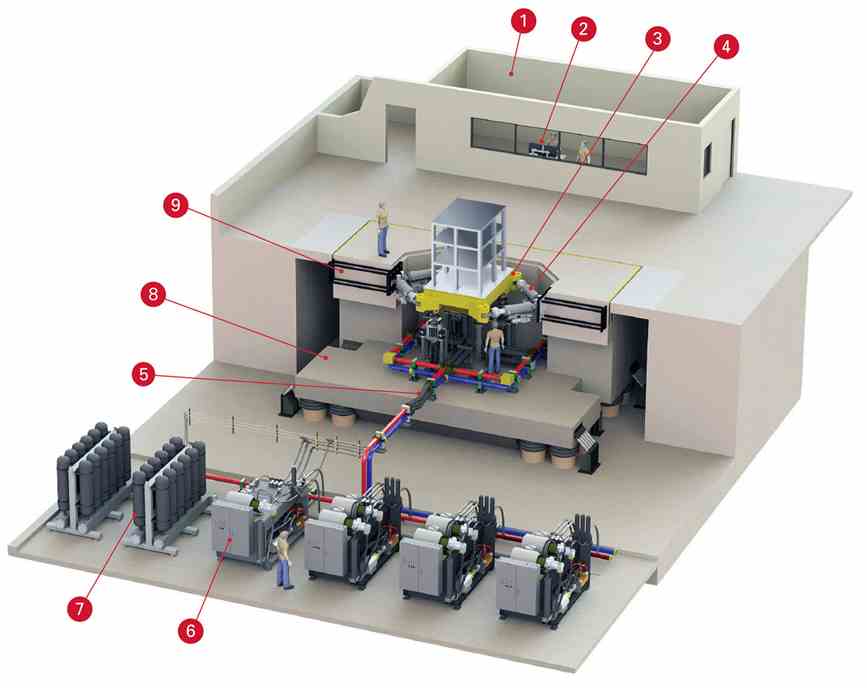

Technical Overview

- Control Room

- User Interface (STEX Pro Software)

- Steel Table

- Seismic Actuators

- Hardline Piping

- Hydraulic Power Units (HPUs)

- Accumulator Bank

- Seismic Reaction Mass

- Actuator Fixturing

|

|

|

1.5m Uniaxial |

|

|

Units |

Square Table |

|

Table Size |

m |

1.5 x 1.5 |

|

ft |

4.92 x 4.92 |

|

|

Number of Actuators |

QTY |

1 |

|

Simulation Frequency (max payload) |

Hz |

0 - 50 |

|

Maximum Payload |

kg |

2,000 |

|

lbs |

4,400 |

|

|

Linear Displacement |

± mm |

200 |

|

± in |

7.87 |

|

|

Linear Velocity |

mm/s |

1000 |

|

in/s |

39.37 |

|

|

Linear Acceleration (at max payload) |

g |

1.1 |

|

|

|

3m Uniaxial |

3m Biaxial |

|

|

Units |

Square Table |

Square Table |

|

Table Size |

m |

3 x 3 |

3 x 3 |

|

ft |

9.84 x 9.84 |

9.84 x 9.84 |

|

|

Number of Actuators |

QTY |

1 |

2 |

|

Simulation Frequency (max payload) |

Hz |

0 - 50 |

0 - 50 |

|

Maximum Payload |

kg |

10,000 |

10,000 |

|

|

lbs |

22,000 |

22,000 |

|

Linear Displacement |

|

|

|

|

Longitudinal (X) |

± mm |

250 |

250 |

|

± in |

9.84 |

9.84 |

|

|

Lateral (Y) |

± mm |

N/A |

250 |

|

± in |

N/A |

9.84 |

|

|

Vertical (Z) |

± mm |

N/A |

N/A |

|

± in |

N/A |

N/A |

|

|

Linear Velocity |

|

|

|

|

Longitudinal (X) |

mm/s |

1000 |

1000 |

|

in/s |

39.37 |

39.37 |

|

|

Lateral (Y) |

mm/s |

N/A |

1000 |

|

in/s |

N/A |

39.37 |

|

|

Vertical (Z) |

mm/s |

N/A |

N/A |

|

in/s |

N/A |

N/A |

|

|

Linear Acceleration (max payload) |

|

|

|

|

Longitudinal (X) |

g |

1 |

1 |

|

Lateral (Y) |

g |

N/A |

1 |

|

Vertical (Z) |

g |

N/A |

N/A |

|

|

Units |

4m 6DOF |

5m 6DOF |

|

|

Square Table |

Square Table |

|

|

Table Size |

m |

4 x 4 |

5 x 5 |

|

ft |

13.12 x 13.12 |

16.40 x 16.40 |

|

|

Number of Actuators |

QTY |

8 |

8 |

|

Simulation Frequency (max payload) |

Hz |

0 – 50 |

0 - 50 |

|

Maximum Payload |

kg |

20,000 |

30,000 |

|

|

lbs |

44,000 |

66,000 |

|

Linear Displacement |

|

|

|

|

Longitudinal (X) |

± mm |

300 |

400 |

|

± in |

11.81 |

15.75 |

|

|

Lateral (Y) |

± mm |

300 |

400 |

|

± in |

11.81 |

15.75 |

|

|

Vertical (Z) |

± mm |

150 |

250 |

|

± in |

5.9 |

9.84 |

|

|

Linear Velocity |

|

|

|

|

Longitudinal (X) |

mm/s |

1500 |

1500 |

|

in/s |

59.05 |

59.05 |

|

|

Lateral (Y) |

mm/s |

1500 |

900 |

|

in/s |

59.05 |

35.43 |

|

|

Vertical (Z) |

mm/s |

1000 |

1000 |

|

in/s |

39.37 |

39.37 |

|

|

Linear Acceleration (max payload) |

|

|

|

|

Longitudinal (X) |

g |

1.5 |

1.5 |

|

Lateral (Y) |

g |

1.5 |

1.5 |

|

Vertical (Z) |

g |

1 |

1 |

- All specifications can be customized

MTS is well known for its seismic expertise and eagerness to work with customer's specific needs. Many of the largest seismic tables in the world utilize MTS actuators and seismic control technology. Full scale structures can be tested in a controlled laboratory setting using massive or multiple seismic tables being controlled together.

Tongji University University of California - San Diego University of Nevada - Reno

|

|

|

1.5m Uniaxial |

3m Uniaxial |

3m Biaxial |

4m 6DOF |

5m 6DOF |

354.20 6DOF |

|

|

Units |

Square Table |

Square Table |

Square Table |

Square Table |

Square Table |

Square Table |

|

Table Size |

m |

1.5 x 1.5 |

3 x 3 |

3 x 3 |

4 x 4 |

5 x 5 |

2.2 x 2.2 |

|

ft |

4.92 x 4.92 |

9.84 x 9.84 |

9.84 x 9.84 |

13.12 x 13.12 |

16.40 x 16.40 |

7.2 x 7.2 |

|

|

Number of Actuators |

QTY |

1 |

1 |

2 |

8 |

8 |

6 |

|

Simulation Frequency (max payload) |

Hz |

0 - 50 |

0 - 50 |

0 - 50 |

0 – 50 |

0 - 50 |

0 - 100 |

|

Maximum Payload |

kg |

2,000 |

10,000 |

10,000 |

20,000 |

30,000 |

2,000 |

|

lbs |

4,400 |

22,000 |

22,000 |

44,000 |

66,000 |

4400 |

|

|

Linear Displacement |

|

|

|

|

|

|

|

|

Longitudinal (X) |

± mm |

200 |

250 |

250 |

300 |

400 |

125 |

|

± in |

7.87 |

9.84 |

9.84 |

11.81 |

15.75 |

4.92 |

|

|

Lateral (Y) |

± mm |

N/A |

N/A |

250 |

300 |

400 |

110 |

|

± in |

N/A |

N/A |

9.84 |

11.81 |

15.75 |

4.33 |

|

|

Vertical (Z) |

± mm |

N/A |

N/A |

N/A |

150 |

250 |

140 |

|

± in |

N/A |

N/A |

N/A |

5.9 |

9.84 |

5.51 |

|

|

Linear Velocity |

|

|

|

|

|

|

|

|

Longitudinal (X) |

mm/s |

1000 |

1000 |

1000 |

1500 |

1500 |

1300 |

|

in/s |

39.37 |

39.37 |

39.37 |

59.05 |

59.05 |

51.18 |

|

|

Lateral (Y) |

mm/s |

N/A |

N/A |

1000 |

1500 |

900 |

1300 |

|

in/s |

N/A |

N/A |

39.37 |

59.05 |

35.43 |

51.18 |

|

|

Vertical (Z) |

mm/s |

N/A |

N/A |

N/A |

1000 |

1000 |

1700 |

|

in/s |

N/A |

N/A |

N/A |

39.37 |

39.37 |

69.93 |

|

|

Linear Acceleration (max payload) |

|

|

|

|

|

|

|

|

Longitudinal (X) |

g |

1.1 |

1 |

1 |

1.5 |

1.5 |

3.3 |

|

Lateral (Y) |

g |

N/A |

N/A |

1 |

1.5 |

1.5 |

3.4 |

|

Vertical (Z) |

g |

N/A |

N/A |

N/A |

1 |

1 |

6.3 |

- All linear translation, velocity and acceleration values are based on single degree of freedom table movement about, or from the table-top center.

- All velocity and acceleration values are peak levels. Indicated levels of performance are not achievable throughout the simulation frequency range.

- Maximum performance is only achievable when payload is mounted wholly within 1m radius (in X-Y plane) of the table center. Stated performance cannot be realized with all specimens as it is dependent on specimen modes and attachment to the table.

- Assumes solid steel test payload rigidly mounted above the table-top center

Get The Most Out Of Your Investment

Our experts are here to help keep you up and running.

Related Products, Parts or Accessories

Modular Components for Civil Engineering Test Applications

STEX Pro Software

Civil Hybrid Simulation

Multi-Axial Subassemblage Test System (MAST)

Seismic Isolation Bearing Test System

Looking for more products?

Go to Solution FinderCONTACT AN MTS REP TODAY

Ready for a quote or need more information? We have applications engineers ready to help. Request A QuoteResources

Improving the Seismic Performance of Earthen Structures

Researchers at Pontificia Universidad Javeriana subject eart…

Conducting Seismic Analysis of Historical Buildings

Mariano Galvez University works to protect architectural pat…

Network for Earthquake Engineering Simulation (NEES): On Solid Ground

MTS helps UCSD maintain the Large High-Performance Outdoo…

Seismic Testing of Full-Scale Wooden Structures

Colorado School of Mines tests wooden structures on UCSD'…

MTS Degree-of-Freedom (DOF) Control

Sophisticated tool enables precise control of complex sei…

Hybrid Simulation Technologies & Methods for Civil Engineering

2018 Worldwide Seminar Series

Leverage MTS Civil Hybrid Simulation Expertise

Step-by-step Quasi-Static and …

Solutions for Multi-Hazard Engineering

Replicate combined, wind, fire, earthquake, wave or blast ev…

The MTS Software Approach to Multidimensional Seismic Test Applications

STEX Pro Seismic Simulation & Qualification Capabilit…

Testing CLT Building Components

Fast + Epp and UNBC test Cross-Laminated Timber shear wal…

New Tools for Multi-Platform Hybrid Simulation

Leverage the University of Toronto UT-SIM standardized fr…

University of Minnesota MAST Lab

Testing full-scale civil structures in six degrees of fre…

University of Minnesota: Debugging Design Codes

6DOF testing of full-scale civil structures and component…