Acumen® Electrodynamic Test Systems

With force capacities up to 12kN or down to milli-Newtons, these clean and quiet systems can extend energy-efficient electrodynamic testing to many applications. The system's intuitive visual displays and software graphics simplify test setup, monitoring and modification, and the sturdy design delivers high precision and accuracy.

Applications

- Dynamic Mechanical Analysis (DMA)

- Tension

- Torsion

- Low-force Testing

- Fatigue Testing

- Dynamic Characterization

- Compression

- Bend

- Flex

Test Specimens

-

Polymers

- Elastomeric Materials

- Elastomers

- Plastics

- Polymers

- Rubber

- Biomaterials and Medical Devices

-

Composites

- Carbon Fiber

- Ceramic Matrix Composites

- Composites

- Metal Matrix Composites

- Polymer Matrix

- Ceramics

- Consumer Products & Packaging

- Microelectronics

Test Standards

- ISO 14801

- ISO 6475

- ASTM F1717

- ASTM F2077

- ISO 7206

- ASTM 1440

- ASTM F543

- ASTM F1800

- ISO 14879

- ASTM F3140-17

- ASTM D7028

- ASTM D5992

- ASTM D5023

- ASTM D5024

- ASTM D5026

- ASTM D5418

- ISO 6721-4

- ISO 6721-5

- ISO 1099

- ASTM 466-96

- ASTM 468-90

- ASTM E606

- ASTM D3479

- ASTM E466

- ASTM E2368

- EUR 22281 EN

- ASTM E647

- ASTM E399

- ASTM E1820

- ASTM 399-17

- ISO 6892

- ASTM D412

- ASTM D882

- ASTM 527-2

- ASTM 527-3

- ISO 7800

- ASTM A938

- ASTM D1043

- ASTM D5279

- ASTM F383

- ISO 5835

- ISO 9268

- ISO 80369-1

- ISO 6721-12

Key Product Features

Easy, Intuitive Use

Simple installation, setup, test monitoring and modification

Accurate / Repeatable Results

Patent-pending software algorithms provide auto-tuning

Energy Efficient

Electric actuation uses less energy

Innovative Technology

Industry-leading performance, with up to 12 kN force capacity and axial/torsional options

Model Comparison

Acumen 1

- Dynamic force: 1250 N (281 (lbf)

- Static force: 850 N (191 lbf)

- Actuator dynamic stroke: 70 mm (2.75 in)

- Tabletop

Acumen 3

- Dynamic force: 3000 N (670 lbf)

- Static force: 2000 N (450 lbf)

- Actuator dynamic stroke: 70 mm (2.75 in)

- Dynamic torque rating: +/- 30 Nm (265 in-lb)

- Static torque rating: +/- 21 Nm (185 in-lb)

- Tabletop

- Available in standard or axial/torsional configurations

Acumen 12

- Dynamic force: 12000 N (2697 lbf)

- Static force: 8500 N (1910 lbf)

- Actuator dynamic stroke: 70 mm (2.75 in)

- Dynamic torque rating: +/-120 Nm (1056 in-lb)

- Static torque rating: +/- 84.8 Nm (746 in-lb)

- Floor-standing

- Available in standard or axial/torsional configurations

Featured Case Studies

Full Product Information

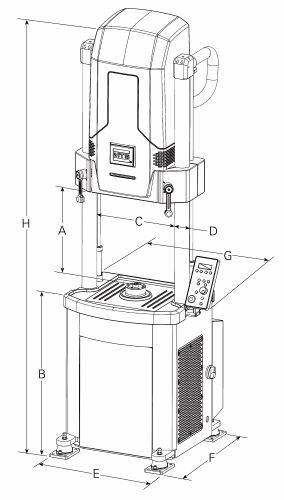

Acumen 1 Specifications

|

|

DIAGRAM |

MODEL |

|

LOAD FRAME SPECIFICATIONS1 |

DETAIL |

ACUMEN 1 |

|

Dynamic force² |

|

1250 N (281 lbf) |

|

Static force² |

|

850 N (191 lbf) |

|

Actuator dynamic stroke |

|

70 mm (2.75 in) |

|

Angular displacement |

|

– |

|

Dynamic performance |

|

≤100 Hz |

|

Minimum test space height³ |

A |

26 mm (1.02 in) |

|

Maximum test space height⁴ |

A |

603 mm (23.74 in) |

|

Working height⁵ |

B |

133 mm (5.24 in) |

|

Test space width |

|

|

|

(measured between columns) |

C |

375 mm (14.76 in) |

|

Base plate design |

|

T-Slot |

|

|

|

(industry standard: 8 mm) |

|

Column diameter |

D |

63.5 mm (2.5 in) |

|

Frame footprint width |

E |

550 mm (21.62 in) |

|

Frame footprint depth⁶ |

F |

485 mm (19.09 in) |

|

Overall width⁶ |

|

|

|

(with frame-mounted controller) |

G |

679 mm (26.73 in) |

|

Overall height⁷ |

H |

1511 mm (59.49 in) |

|

Weight |

|

159 kg (350 lb) |

|

Noise level - typical⁸ |

|

47 dbA |

|

Noise level - maximum⁸ |

|

69 dbA |

|

Mounting |

|

Tabletop: Vertical |

|

Standard load cell |

|

1.5 kN Accel Comp |

|

Operating temperature |

|

+5C° to +40C° |

|

Cooling |

|

Automated forced air |

|

Electrical requirements⁹ |

Voltage - VAC |

100-120 (200-240) |

|

|

Frequency - Hz |

50 - 60 |

|

|

Current - Amps |

7 (4) |

|

|

Phase |

Single |

Acumen 3 and 12 Specifications

|

|

DIAGRAM |

MODEL |

|

|

|

|

LOAD FRAME SPECIFICATIONS1 |

DETAIL |

ACUMEN 3 |

ACUMEN 3 A/T |

ACUMEN 12 |

ACUMEN 12 A/T |

|

Dynamic force² |

|

3000 N (670 lbf) |

3000 N (670 lbf) |

12000 N (2697 lbf) |

12000 N (2697 lbf) |

|

Static force² |

|

2000 N (450 lbf) |

2000 N (450 lbf) |

8500 N (1910 lbf) |

8500 N (1910 lbf) |

|

Dynamic torque rating |

|

– |

±30 Nm (265 in-lb) |

– |

±120 Nm (1056 in-lb) |

|

Static torque rating |

|

– |

±21 Nm (185 in-lb) |

– |

±84.8 Nm (746 in-lb) |

|

Actuator dynamic stroke |

|

70 mm (2.75 in) |

70 mm (2.75 in) |

70 mm (2.75 in) |

70 mm (2.75 in) |

|

Angular displacement |

|

– |

±135° |

– |

±135° |

|

|

|

|

±20 revolutions |

|

±20 revolutions |

|

|

|

|

0.001 rpm - 100 rpm |

|

0.001 rpm - 100 rpm |

|

|

|

|

continuous rotation |

|

continuous rotation |

|

|

|

|

to 350 rpm |

|

to 100 rpm |

|

Dynamic performance |

|

≤100 Hz |

≤100 Hz |

≤100 Hz |

≤100 Hz |

|

Minimum test space height³ |

A |

26 mm (1.02 in) |

0 mm (0.00 in) |

55 mm (2.17 in) |

0 mm (0.00 in) |

|

Maximum test space height⁴ |

A |

819 mm (32.24 in) |

603 mm (23.74 in) |

985 mm (38.8 in) |

810 mm (31.9 in) |

|

Working height⁵ |

B |

133 mm (5.24 in) |

133 mm (5.24 in) |

815 mm (32.1 in) |

815 mm (32.1 in) |

|

Test space width |

C |

460 mm (18.11 in ) |

460 mm (18.11 in ) |

460 mm (18.11 in ) |

460 mm (18.11 in ) |

|

(measured between columns) |

|

|

|

|

|

|

Base plate design |

|

T-Slot |

T-Slot |

T-Slot |

T-Slot |

|

|

|

(industry standard: 8 mm) |

(industry standard: 8 mm) |

(industry standard: 14mm) |

(industry standard: 14 mm) |

|

Column diameter |

D |

63.5 mm (2.5 in) |

63.5 mm (2.5 in) |

76.2 mm (3 in) |

76.2 mm (3 in) |

|

Frame footprint width |

E |

634 mm (24.96 in) |

634 mm (24.96 in) |

651 mm (25.6 in) |

651 mm (25.6 in) |

|

Frame footprint depth⁶ |

F |

501 mm (19.72 in) |

501 mm (19.72 in) |

817 mm (32.2 in) |

817 mm (32.2 in) |

|

Overall width⁶ |

G |

764 mm (30.08 in) |

764 mm (30.08 in) |

805 mm (31.7 in) |

805 mm (31.7 in) |

|

(with frame-mounted controller) |

|

|

|

|

|

|

Overall height⁷ |

H |

1726 mm (67.95 in) |

1726 mm (67.95 in) |

2810 mm (110.7 in) |

2810 mm (110.7 in) |

|

Weight |

|

188 kg (415 lb) |

230 kg (507 lb) |

953 kg (2100 lb) |

1043 kg (2300 lb) |

|

Noise level - typical⁸ |

|

47 dbA |

47 dbA |

62 |

62 |

|

Noise level - maximum⁸ |

|

69 dbA |

69 dbA |

78 |

78 |

|

Mounting |

|

Tabletop: Vertical |

Tabletop: Vertical |

Floor: Vertical |

Floor: Vertical |

|

Standard load cell |

|

3 kN Accel Comp |

3 kN Accel Comp |

12 kN Accel Comp |

12 kN Accel Comp |

|

Operating temperature |

|

+5C° to +40C° |

+5C° to +40C° |

+5C° to +40C° |

+5C° to +40C° |

|

Cooling |

|

Automated forced air |

Automated forced air |

Automated forced |

Automated forced |

|

|

|

|

|

air & self contained |

air & self contained |

|

|

|

|

|

water cooled |

water cooled |

|

Electrical requirements⁹ |

Voltage - VAC |

200-240 |

200-240 |

200-240 |

200-240 |

|

|

Frequency - Hz |

50 - 60 |

50 - 60 |

50 - 60 |

50 - 60 |

|

|

Current - Amps |

10 |

20 |

38 |

38 |

|

|

Phase |

Single |

Single |

Single |

Single |

|

|

|

|

|

|

|

|

1.Specifications subject to change without notice. |

|

|

|

||

|

2.Verifiable with MTS compression spring test. Performance may vary depending on test type, test set-up, frequency, specimen, environment and other factors. |

|||||

|

3.Assumes standard system load cell installed, crosshead fully lowered and actuator fully extended to end of the dynamic stroke. |

|||||

|

4.Assumes standard system load cell installed, crosshead fully raised and actuator fully retracted to end of the dynamic stroke. |

|||||

|

5.From table to top of work surface; without optional isolation pads. |

|

|

|

||

|

6.For systems with optional test area enclosure, add 98 mm (3.8 in.) to dimension F and 45 mm (1.8 in) to dimension G for overall system dimensions. |

|||||

|

7.Measured with crosshead fully raised, without optional isolation pad. |

|

|

|

||

|

8.Typical usage at 1 m, free field. Noise level varies depending upon test type, specimen, environment and other factors. |

|

||||

|

9.Acumen 1 current rated at 100 (200) VAC. Acumen 3 current rated at 200 VAC. |

|

|

|||

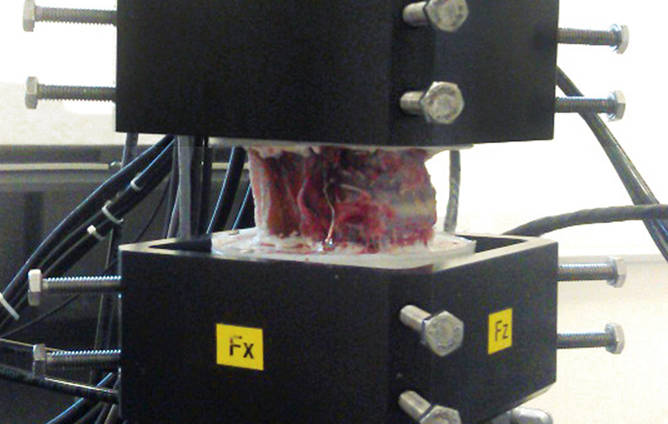

Supporting the mission of biomedical researchers and manufacturers

Key options for biomedical testing:

- 12 kN force capacity

- Conducts orthopaedic studies to 4x body weight

- Additional axial/torsional capability

- Higher speeds, higher torque and more continuous rotation to test a wider range of materials

- Precise low-force measurement

- Easily tests fragile, intricate or lightweight specimen

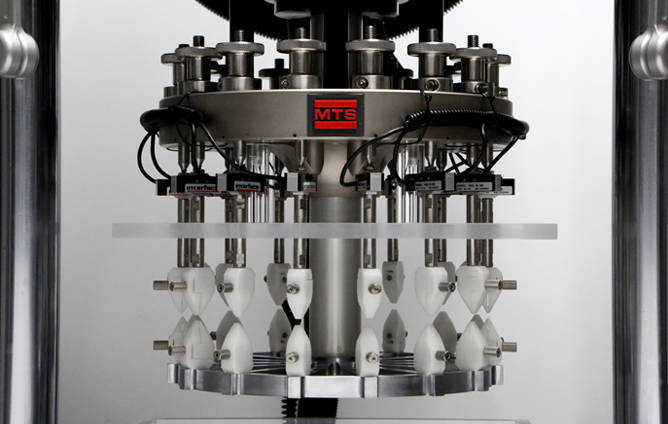

- Multi-sample fatigue fixture

- Triggers independent data acquisition for 15 samples at once

Use MTS Acumen systems to test:

- Orthopaedic constructs: small joints, c-spine, finger, ankle

- Trauma devices: plates, screws, constructs

- Biomaterials: plastics, soft tissues, hydrogels, ligaments, bones

- Dental materials/devices: cements, plastics, metals

- Vascular devices: stents, grafts

- Packaging and consumables: needles, syringes, packaging, tubing

GET THE MOST OUT OF YOUR INVESTMENT

Our experts are here to help keep you up and running.

Related Products, Parts or Accessories

Series 651 Environmental Chambers

Multi-Sample Fatigue Fixture

Axial Extensometers with 25 mm (1 in.) Gage Length

Landmark® Servohydraulic Test Systems

TestSuite Software

Looking for more products?

Go to Solution FinderResources

Electric Actuation for Low Force Applications

MTS application engineers discuss advantages of electric act…

Electrodynamic Excellence

MTS Acumen test systems offer advantages in system control, …

Changing Scope of DMA

MTS engineers discuss the latest in dynamic mechanical analy…

New Optical Extensometer

Simplified non-contacting axial strain measurement & con…

Monitoring Fracture of Multiple Samples Simultaneously

Techniques to accelerate endovascular device testing.

Decreasing Test Time for Nitinol Devices

Examining fatigue life of nickel titanium alloys used in vas…

Using DMA for Materials Characterization

Elastomers, polymers and shape memory alloys - MTS helps res…